Project description

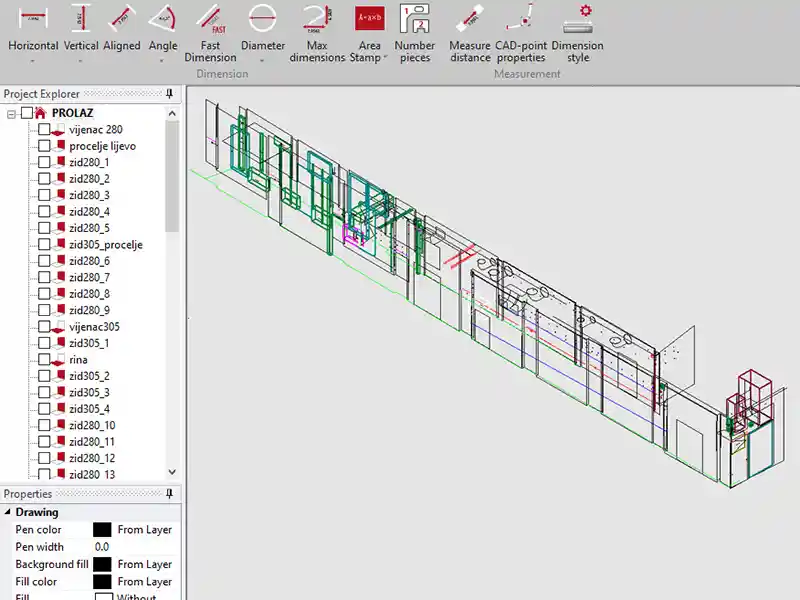

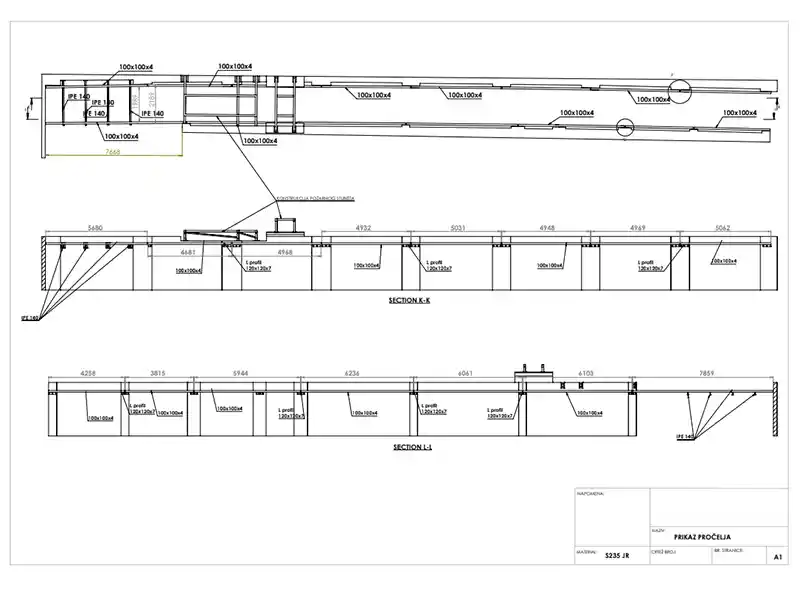

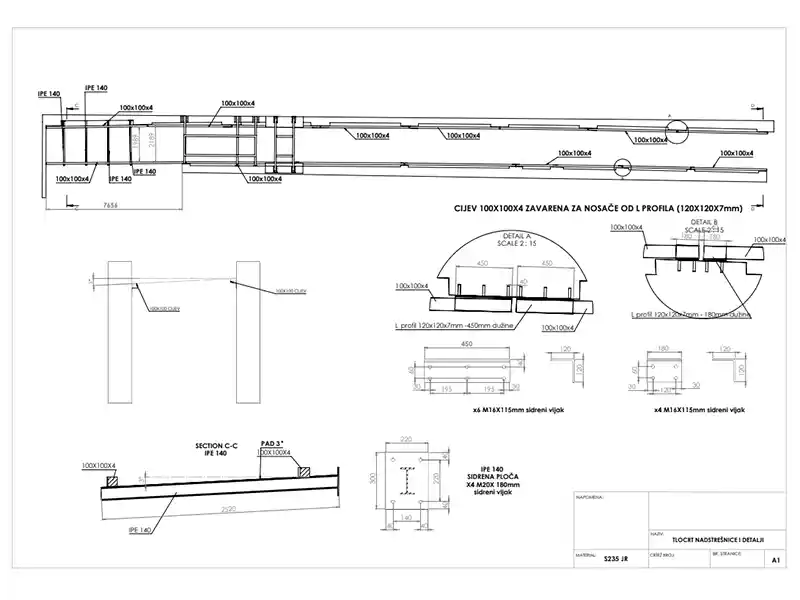

The task was to measure the space between two buildings for the construction of a canopy that would allow for unhindered movement during rain and bad weather. The project required precision due to various obstacles on the facade of the buildings, including air conditioners, chimneys, windows and other structural elements.

Challenges

- Precise measurement of passage between two objects with numerous obstacles

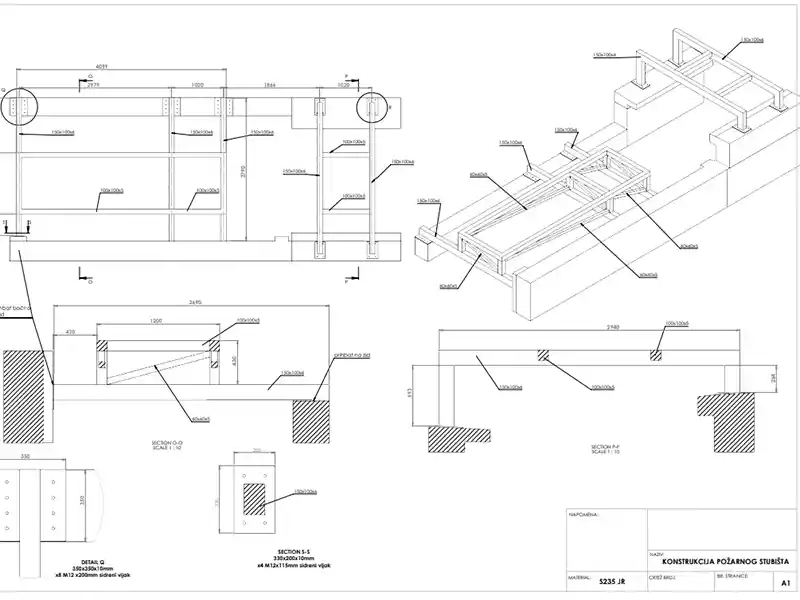

- Adequate construction of a canopy that must be adapted to existing elements

- Transferring information to constructors who were not present during the survey

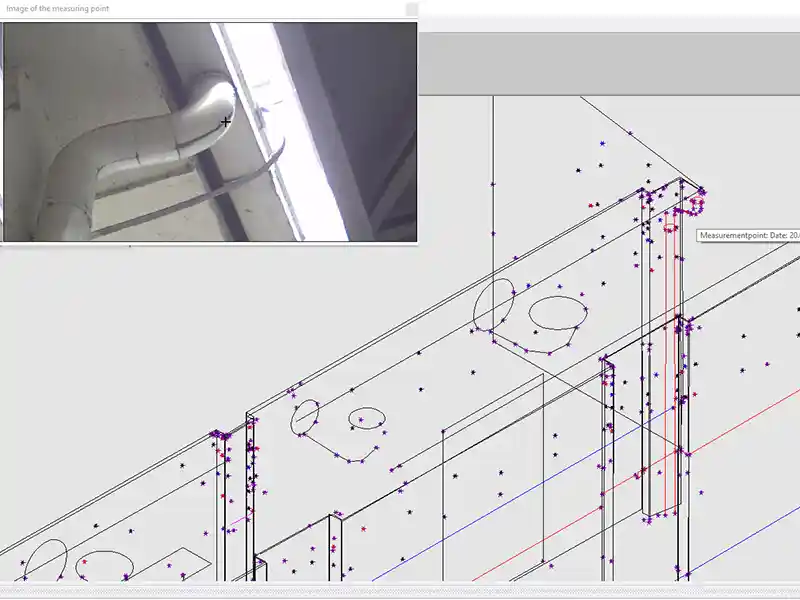

The Flexijet device was used to measure the entire space in detail. One of the key advantages of this device is the ability to photograph each measurement point, which allows the precise location of each measured point to be identified later during construction. This feature proved to be extremely useful in the planning process, allowing designers who were not present at the survey to clearly understand the complexity and details of the construction site. The survey process lasted 2 hours, during which every important point of the space between the two buildings was measured in detail and photographed. Thanks to the technology offered by the Flexijet, the team was able to efficiently document and archive each measurement with a corresponding photograph.

Project summary

Using the Flexijet measuring device, the project of building a canopy between two buildings was successfully realized despite numerous challenges. The technology of measuring and photographing each point proved to be crucial in the precise planning and construction, enabling the team to communicate effectively and implement the plan without errors. This case study serves as an example of how advanced technologies can facilitate complex architectural and engineering tasks, increasing efficiency and reducing the time frame of project realization.

- Measurement time: 2 hours

Flexijet operator for 3D measurement and surveying drawings:

Josip Hruškar

Project client and executor: Metalkov MB d.o.o.

Flexijet 3D device representative: Flexijet East