Project description

In luxury interiors, every millimeter carries weight, and every detail has its purpose. Especially when it comes to materials like natural stone – elegant, durable, but at the same time technically demanding and sensitive to the slightest mistake. This was exactly the case with the kitchen in a private house on Zagreb’s Sv. Duh, where the client had a clear vision: stone countertops and wall coverings that would fit the space perfectly, without compromise and without room for improvisation.

In a world where every mistake can mean thousands of euros in loss, the solution was not classic manual measurement, but technology that offers what luxury materials demand – absolute precision. Discover below how the Flexijet 3D system became a key ally in the realization of this demanding but spectacular project – from digital measurement to perfectly mounted stone surfaces that will take your breath away.

Challenges:

The investor ordered the production of natural stone kitchen surfaces for the kitchen island countertop, the countertop with sink, and wall cladding with holes for two sockets. Given that these are expensive materials that do not tolerate errors, it was necessary to ensure maximum measurement accuracy before starting construction.

Solutions:

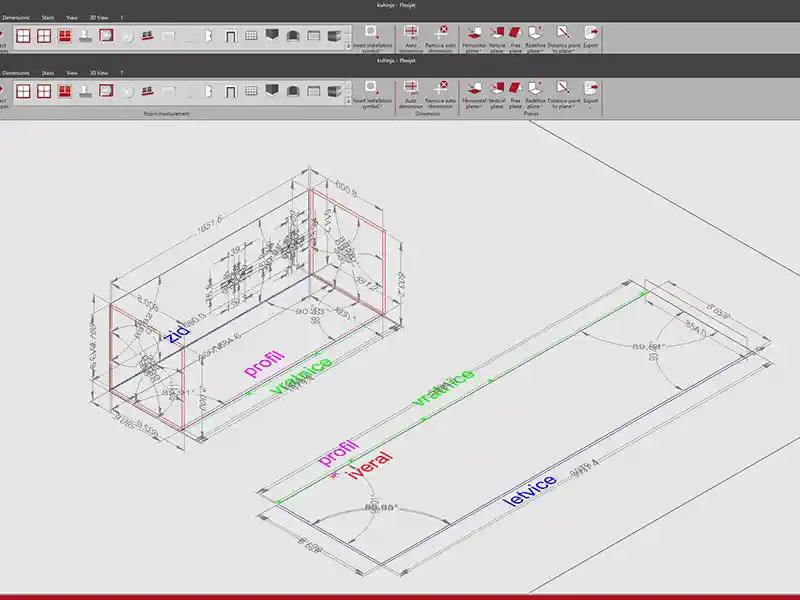

In order to eliminate the possibility of manufacturing errors, a Flexijet 3D digital measurement device was used. A detailed 3D measurement of the already installed kitchen elements was made, including:

- the exact dimensions of the kitchen island and its edges,

- position of the elements with the sink in relation to the wall,

- heights and depths for stone processing,

- the positions of two sockets that had to be precisely cut into the wall covering.

The data obtained from the measurement was imported into CAD software and prepared for processing on CNC machines. This enabled:

- making a stone slab with absolute accuracy,

- precise processing of openings for sockets without the need for manual corrections,

- perfect fit of all elements already at the first assembly.

Advantages of FlexiJet 3D measurements

No additional costs due to errors

Thanks to the precise 3D measurement of the kitchen using the Flexijet device, additional costs that would otherwise arise from errors in the manufacture or installation of stone worktops and wall coverings are completely avoided. This prevents unnecessary expenses for additional materials, subsequent corrections, additional working hours or multiple organized transport.

Faster processing, faster assembly

Precise and detailed data enabled CNC stone processing without additional on-site checks. This significantly accelerated the entire process – from material processing to final assembly – and enabled the project to be realized in a shorter time frame.

Elements that fit perfectly

The stone elements – the island worktop, the worktop with the sink and the wall covering with socket openings – were manufactured with millimetre precision, completely adapted to the existing kitchen elements. Thanks to this, the installation was quick and flawless, without the need for additional adjustments on site.

Reliability from design to finished product

CAD designs, generated directly from Flexijet 3D software, enabled stone processing with a high level of reliability. This virtually eliminated the possibility of human error during the production process, which is especially important when dealing with expensive materials such as natural stone.

Conclusion

Thanks to the use of the Flexijet 3D system, the elements were manufactured with millimetric precision and installed without any additional finishing on site. The result is an aesthetically and functionally flawless kitchen with a luxurious stone countertop that fits perfectly into the existing space.

This project once again confirms that when working with valuable materials and limited tolerances – precise 3D measurement is not an option, but a necessity.