Project description

The reconstruction of the Pical Hotel in Poreč included several phases of interior modernization, including the creation of a new sintered quartz bar. Such elements require exceptional measurement precision, especially when they contain curved surfaces and radii that must be defined without deviations. At the request of the company Lateramen d.o.o., responsible for the creation of the quartz bar, a detailed 3D measurement was carried out using the Flexijet system and technical documentation was prepared as a basis for accurate and safe production.

Project challenges

Our partner, the company Lateramen d.o.o., took on the production of a bar that contains multiple curved surfaces. For proper CNC cutting, it was necessary to:

- obtain absolutely precise radii,

- document the actual condition of the space,

- prepare technically correct designs that can be used without corrections.

Sintered quartz does not allow for mistakes – an error of just a few millimeters can result in expensive re-cutting and delays in execution.

Traditional manual measurement methods could not ensure sufficient accuracy, so it was decided to use Flexijet 3D, a measurement system of which we – Studio Element d.o.o. are the regional representative.

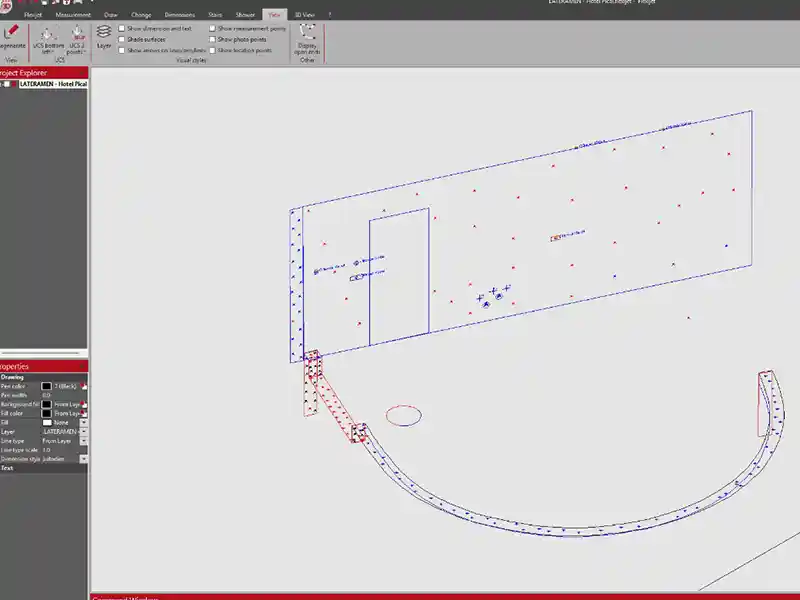

Solution: fFexijet 3D surveying and technical drawing preparation

La Foja Interior Design performed a field measurement of the bar using Flexijet 3D, which provided Lateramen d.o.o. with ultra-precise measurement data on the radii and geometry of the space.

Flexijet is used in this project:

- enabled precise definition of all radii

- provided measurement data without deviations

- removed the uncertainty of CNC cutting

- provided a reliable basis for technical preparation and error-free installation

Our company Studio Element d.o.o., based on these measurements, created:

- basis for CAD drawings of the bar,

- preparation of measurements and basis for preparation of production,

- technical specifications that enable safe production and assembly without corrections.

Results and delivered value

- High accuracy of the base and survey drawings

The drawings fully correspond to the actual measured condition, including all radii and curvatures. - Elimination of manufacturing errors

Lateramen was able to begin preparation for cutting quartz with complete confidence in the measurement documentation and error-free installation - Saving materials and time

Precise 3D measurements reduced the risk of re-cutting, which is extremely important with quartz. - Better coordination of all participants

Each company had clear work parameters, which enabled a quality project flow.

This project shows how the collaboration of three specialized teams and the application of cutting-edge technology results in precise, safe, and high-quality performance.

Studio Element d.o.o., as a representative of the Flexijet 3D system and a technical partner in the preparation of measurement drawings and CAD bases, enabled the company Lateramen d.o.o. to manufacture and install a bar with complex radii without deviations and with a high level of production safety.

The combination of: precise 3D measurements, quality technical documentation and quality cooperation between contractors proved to be key to the successful manufacture of an element made of sintered quartz.

They participated in the project

Flexijet 3D device representative and 3D measurement service provider:

Studio Element d.o.o., Dolac 1, Zagreb

Client and contractor – production of sintered quartz work surfaces:

Lateramen d.o.o., Žiškovec 41, 40000 Čakovec

lateramen.keramika@gmail.com

+385915257197

Provider of 3D measurement service using the Flexijet system:

La Foja Interior Design (vl. Josipa Vuković)

Via dell castello 2A, Momjan

la.foja.design@gmail.com

+385915118221