Luxury Villa OX

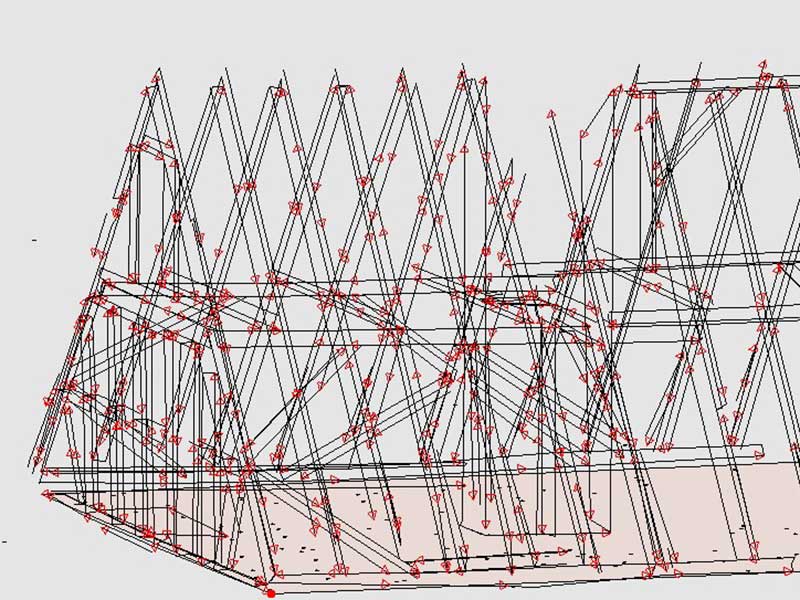

Luxury Villa OX Project description Villa OX is a luxurious private villa in Istria with over 400 m² of living space spread over three floors – including a spacious living room, kitchen, six bedrooms with bathrooms, utility rooms in the basement and connected communication zones such as staircases, niches and hallways.The team’s task was to precisely measure the entire building in order to create custom-made furniture and interior finishes, while fully integrating each element into the existing architecture. The complexity of the project required technology that ensures millimeter accuracy and full digital control over all stages – from measurement to final assembly. FlexiJet 3D in the service of precision For the purposes of this project, we conducted a complete 3D survey using the Flexijet system – a device that enables laser-accurate space recording and direct synchronization with CAD software. All areas of the villa, including demanding elements such as curved walls, staircases and niches, were digitized in real time, eliminating the need for manual sketches and repeated visits to the site.The resulting digital model served as the basis for designing furniture, wall coverings and seating elements in the living room. This ensured the perfect adaptation of all components to the architectural geometry of the building. Final performance Based on the Flexijet measurements, Design360 manufactured and installed all custom furniture, including: complete living room with integrated seating elements kitchen with custom cabinets and finishes, six bedrooms with bathrooms, hallways, staircases and utility rooms (laundry room, engine room, entertainment area).The combination of precise 3D measurements and quality workmanship resulted in an interior that exudes functionality and elegance – without the need for corrections or additional measurements. Result: A modern, custom-made home Villa OX today represents an example of the flawless collaboration between digital technology and masterful craftsmanship.Thanks to the Flexijet 3D system and the expertise of the Studio Element, Articus and Design360 teams, each piece of furniture fits perfectly into the space, creating the impression of an architectural whole in which technology serves design. They participated in the project Flexijet 3D device representative and 3D measurement service provider:Studio Element d.o.o., Dolac 1, Zagrebinfo@3dmjerenje.comDesign, production and assembly: Design 3STO60 d.o.o.Družilovečka 2, Zagrebinfo@design360.hr+38598842101Flexijet operator for surveying and preparation of survey drawings:Articus d.o.o., Dolac 1, Zagrebinfo@articus.hr+3859875208 Flexijet measurement Flexijet measurement Flexijet measurement Flexijet measurements Flexijet measurements Finished product