Project description

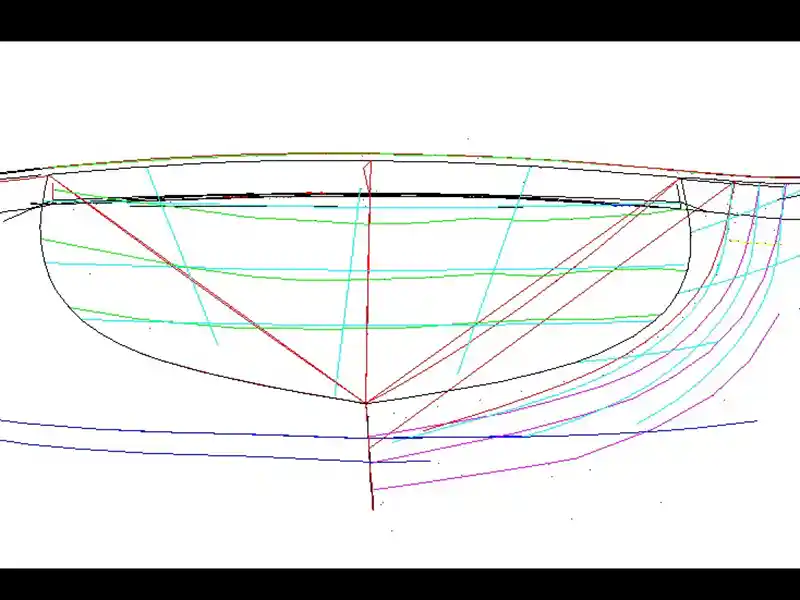

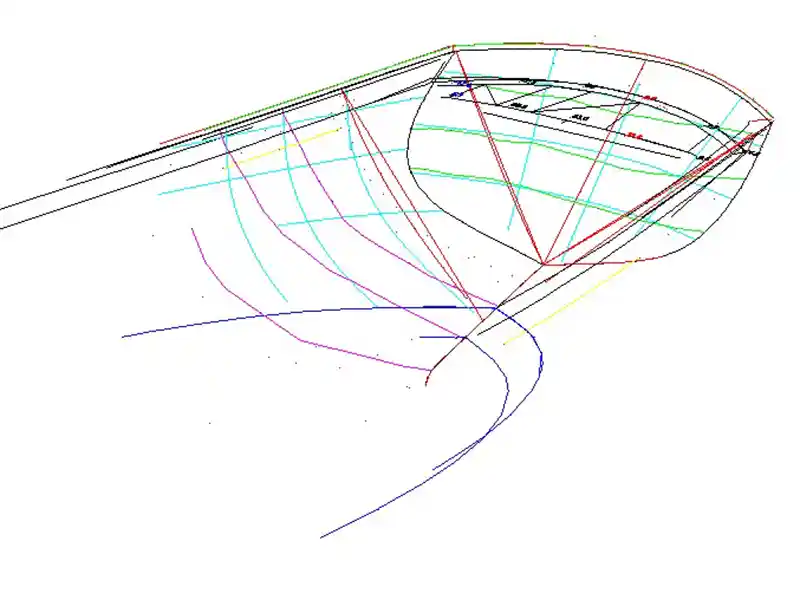

In collaboration with Yacht Pro Solution and main contractor Krištof Amon, the demanding project of upgrading the sailboat Irene was successfully completed. Krištof Amon designed a 5-axis CNC machining for the production of an MDF mold, which then served as the basis for the production of a fiberglass superstructure in polyester technology. A key step in this process was the precise 3D measurement of the entire hull, carried out with the Flexijet 3D system. Thanks to the millimeter-accuracy of laser scanning, the rounded surfaces of the hull were defined in advance, ensuring that the new superstructure would seamlessly continue the existing shape of the sailboat – without any deviations. Special attention was paid to the convex surface of the transom, whose complex geometry required the highest level of precision. Based on the digital model created in Rhino software, an accurate CNC program was generated, eliminating the possibility of errors in execution and achieving complete alignment of all elements.

Project specifics

In projects like this one, where the sailboat Irenei used to attract attention with her classic lines and maritime elegance, this upgrade further refined her silhouette. In addition to the technical aspect, the story gains special significance thanks to the fact that it was Irene who was chosen for the filming of the Hollywood film Afterburn, starring Samuel L. Jackson, Dave Bautista and Olga Kurylenko. According to the Slovenian media (24ur, Regional Obala, Slovenske Novice, Primorske Novice, Nova TV), Irene was an “Izola beauty” who conquered film producers because of her authentic beauty. The film was shot in Bratislava, and for the purposes of filming on the boat, the team from Izola had to adjust the structure and even modify the height of the mast — further confirming the complexity of the operation and the importance of precise planning

The role of the Flexijet 3D system

No manual sketches and measurement errors

Forget about uncertain measurements, notebooks and measuring “by eye”. The Flexijet 3D system enables laser-precise digitization of spaces and objects in real time, even on curved and irregular surfaces such as a ship’s stern. The result? Reliable data after the first measurement – without the need for subsequent visits or corrections.

Faster preparation of drawings and models

Traditional measurement methods often require additional days to draw up drawings and transfer them to CAD tools. With the Flexijet system, 3D measurement and modeling go hand in hand – measurements are automatically synchronized with CAD software such as Rhino, AutoCAD, ArchiCAD and others. This means that you can start preparing the final model for production on the same day.

Saving time and materials

Any measurement error can be costly: lost material, extra hours of work, frustration in the field. Precise measurement with Flexijet enables accurate planning of all phases of construction or reconstruction, thus reducing the need for subsequent adjustments, waste and unplanned costs. In shipbuilding, architecture and interiors – time = money. And Flexijet saves both.

Precise base for CNC production

When data is collected with Flexijet, it can be used directly to create molds and parts via CNC machines – without manual measurement transfers and additional “cleaning” of the design. In the Irene sailboat project, it was precisely this accuracy that enabled the creation of a mold for the stern superstructure without deviations – perfectly adapted to the existing shape of the boat.

In short, with Flexijet you get:

- control over all phases, from measurement to implementation,

- speed and accuracy in one tool,

- the security of working on proven substrates.

They participated in the project

Contractor on board:

Yacht Pro Solution sa glavnim izvođačem radova Krištofom Amonom

Šmarska cesta 7A, 6000 Koper, Slovenija

info@yps.si, +386 41 804 650

Flexijet 3D device representative and 3D measurement service provider:

Studio Element d.o.o., Dolac 1, Zagreb

info@3dmjerenje.com, +385 98 472 900

Technical challenges and solutions

The main challenge was the complex geometry of the transom, which was almost impossible to capture accurately with traditional tools. Flexijet digitized these curved surfaces without difficulty and provided a perfect match between the existing hull and the new upgrade. As the Studio Element team says:

Why is this project special?

In addition to its technical excellence, the Ireneje Sailing Ship project is also culturally significant:

– the boat was selected for filming a high-budget Hollywood film,

– the preparation for filming was carried out by experts from the Society of Old Boat Lovers in Izola,

– due to the film’s needs, Ireneje underwent adjustments that further enhanced the role of 3D measurements and modeling.

Conclusion

The Irene Sailing Ships project demonstrates how digital precision, innovation and a passion for craft can create something extraordinary – both technically and culturally. Flexijet 3D technology was the foundation for the realization of this sophisticated upgrade, and its success confirms that investing in digital accuracy is essential for high-standard projects – whether they are in the service of nautical or film.