About Flexijet

Flexijet 3D

New generation of digital 3D measuring technology

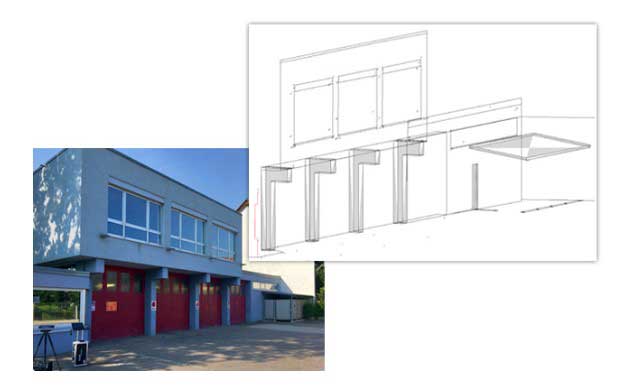

Consistent drive for improvement and open for curtomer ideas and needs have brought about a fully newly developed 3D measuring hardware. Technically, ergonomical and visually completely “thought though” in order to enable even more efficient measuring.

With Flexijet 3D literally anyone can complete measurements quickly, efficiently and economically and estimate dimensions with millimetre precision and input data directly into CAD. Regardless of being a begineer or an expert or a CAD expert, Flexijet 3D enables one-step CAD measurements and offers many advantages with regard to conventional measuring techniques and point clouds of other laser scanners.

Measuring and drawing

Flexijet 3D is different from other measuring systems because it uses original CAD tools like lines, polylines, arches and circles in order to measure and draw. Instead of creating confusing point clouds that require further processing, this system enables the creation of a finished CAD drawing in “real-time” during on-site measurements, eliminating the need for time-consuming post-processing.

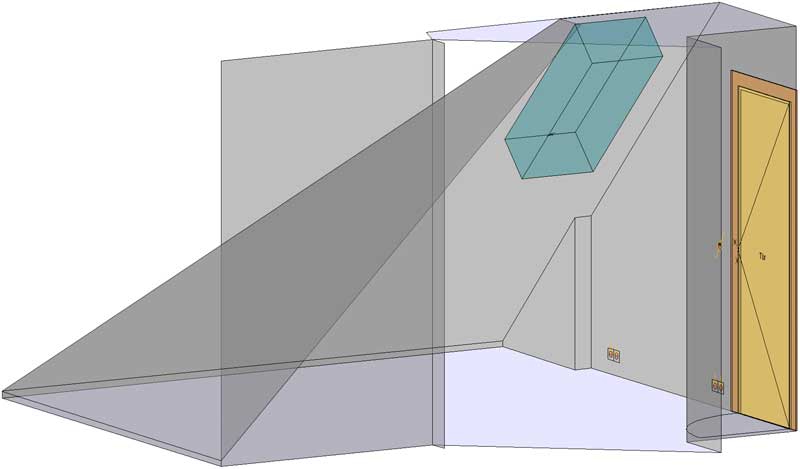

During the measurement process, Flexijet 3D enables the creation of precise three-dimensional CAD models of objects such as walls, doors, arches, openings or the entire room on site. This means that CAD models are created at the same time as the measurement, which ensures high precision and eliminates the need for additional processing.

Before leaving the construction site, the finished CAD model can be compared to the actual condition and checked that all relevant dimensions are recorded correctly, thus ensuring that the model corresponds to reality.

The measurements are understandable for everyone because the intuitive software immediately defines the walls, doors, windows, but also other elements in the room such as electrical and sanitary installations, air conditioners, radiators and many other elements in the room.

The camera’s crosshair display also allows pinpoint targeting when environmental conditions make it difficult to see the laser dot. Communication between the hardware and the laptop is achieved using the built-in WiFi network protocol.

The device provides approximately 8 hours of battery life (depending on engine usage).

The Flexijet 3D has a built-in self-leveling feature and can be operated manually and motorized – via remote control or using the Flexijet Smart Remote app on your smartphone. Measurements can be initiated via the touch sensor on the housing, by remote control or by pressing a button in the FlexiCAD software.

Unique FlexiJet 3D device features

Measuring and drawing

Flexijet 3D is different from other measuring systems because it uses original CAD tools like lines, polylines, arches and circles in order to measure and draw. Instead of creating confusing point clouds that require further processing, this system enables the creation of a finished CAD drawing in “real-time” during on-site measurements, eliminating the need for time-consuming post-processing.

During the measurement process, Flexijet 3D enables the creation of precise three-dimensional CAD models of objects such as walls, doors, arches, openings or the entire room on site. This means that CAD models are created at the same time as the measurement, which ensures high precision and eliminates the need for additional processing.

Before leaving the construction site, the finished CAD model can be compared to the actual condition and checked that all relevant dimensions are recorded correctly, thus ensuring that the model corresponds to reality.

The measurements are understandable for everyone because the intuitive software immediately defines the walls, doors, windows, but also other elements in the room such as electrical and sanitary installations, air conditioners, radiators and many other elements in the room.

Quick space measurement

Flexijet 3D enables quick and precise measurements.

In the measurement software, a 3D space is created with only a few measurement points. With only two points per wall surface and one point each for the floor and ceiling, the room can be drawn in so few steps. There is no need to target the corners of the room as the software automatically joins the corners of walls. The corners of the walls that are connected to each other are precisely drawn during this quick site measurement process.

Rooms can be further detailed as needed, measuring other elements such as roof pitches, doors, windows, pipes, lamps and switches and more.

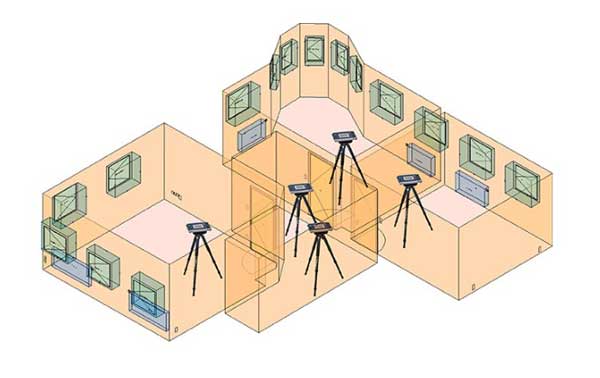

Relocation - measurement without restrictions

Flexijet 3D enables the flexibility of device relocation in situations where it is not possible to record all measurements from one place. If it is necessary to measure adjacent rooms and combine them in the same 3D CAD model, Flexijet 3D can easily do this.

By capturing only two reference points that are visible from both locations, the Flexijet 3D precisely references the measurement, enabling a continuous measurement process. Entire floors or buildings can be easily covered in one CAD drawing.

CAD point projection

Flexijet 3D has more functionality than just precise measurement – it can be an invaluable tool for installation on the construction site. Through various commands such as “Show CAD Point”, you can simply select or click on a CAD point on your laptop and the Flexijet 3D will direct and rotate the laser beam exactly to the selected point on the jobsite.

For example, you can import CAD point drawings for a large commercial office space into Flexijet software. By clicking on a specific point location on the CAD drawing, you can see Flexijet 3D rotate and direct the laser beam exactly to that location on the spot. No more need for measuring tapes, laser levels or drawing lines with chalk. This feature can also be used to mark attachment points on the ceiling or floor.

The possibilities of using this tool are only limited by your imagination. Flexijet 3D enables significant on-site design improvement, giving you precision and practicality.

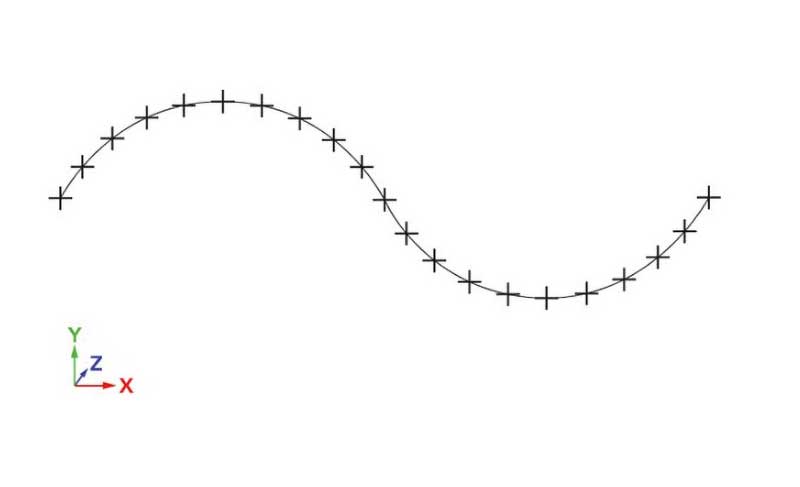

Automatic series of measurements

A feature that is ideal for measuring or drawing curved or uneven surfaces. Draw walls horizontally, vertically or parallel to any inclined, horizontal or vertical surface.

The process involves defining a starting point, a direction and an ending point. Flexijet 3D automatically measures and draws the surface profile.

With a vertical measurement array, ship hulls, for example, can be measured fully automatically. A horizontal series of measurements can be used, for example, to determine a curved wall.

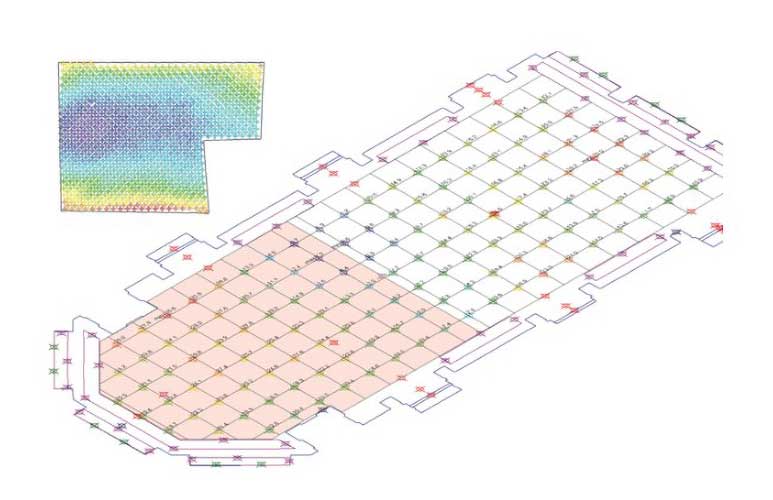

Automatic detection of surface irregularities

Flexijet 3D can scan any surface with predefined steps to create a 3D profile of that surface.

By drawing or measuring a closed contour and converting that object to a mesh, the Surface Scan command can automatically measure all intersection points of the mesh. The different heights are marked with different colors that reveal the unevenness of the surface.

Ideal for surface scanning of floors or walls.

FlexiJet 3D Hardware

Flexijet 3D laser measurement system hardware has an ergonomic design that combines electronic, optical and mechanical components in one device. This design has received global recognition and recently won the prestigious Red Dot Design Award. Flexijet 3D is based on a laser distance meter that, in combination with a rotary/pivot unit, precisely detects coordinates and transfers this data to one of two 3D measurement software, FlexiCAD or FlexijetSTONE.

It features a 7-inch touch screen that allows selection of CAD commands and software functions directly from the measuring device, without the need for access via a laptop or tablet. Setting up the measuring system is quick and easy and is ready for use in just a few minutes.

The Flexijet measuring hardware independently provides WLAN with integrated WiFi for direct connection to the FlexiCAD measuring software. No leveling of the tripod is necessary because the software will automatically level the device. The built-in shock sensor warns of any inadvertent movement of the device to ensure the integrity of the measurement data.

An essential feature of the Flexijet 3D is the possibility of manual or remote control using the supplied remote control or via the Flexijet SmartRemote application, which is available for free for iOS and Android devices.

The Flexijet 3D not only acts as a precise measuring device, but also as an innovative tool that facilitates installation on the construction site. The projection function of Flexijet 3D allows CAD points from drawings to be projected on site using a laser beam. This feature allows you to precisely “plot” objects such as walls, penetration points, attachment points, etc. from CAD drawings.

Measurements can be initiated via the device’s touch sensor, remote control or from a laptop or tablet. In addition to image documentation, the 5-megapixel camera enables optical target selection using the crosshairs in the camera’s live image. This allows measurements to be recorded even in bright sunlight when the laser spot is not clearly visible to the human eye.

The Flexijet 3D measuring set contains

- 7 inch touch screen

- Laser measuring unit

- 5 Megapixel camera

- Tilt sensor

- Shock sensor

- Integrated WI-FI

- powerful Lithium-ion battery (100 Wh)

- high quality carbon tripod adjustable in height with transport bag

High-quality transport case contains

- Laptop desk on an aluminum tripod

- Notebook bag

- Compartments for accessories

Accessories

- remote control - Xbox controller

- charger

- laser glasses

- measurement points

- Aluminum auxiliary support

FlexiCAD software for measurement one license

Special System Features

One person operation

the measurement is performed by one person which reduces labor costs

Automatic levelling

no need to manually adjust the stand

NO TEMPLATES NEEDED

there is no need to create actual templates

Immediate space visualisation

on-site measurement verification with automatic dimensioning and point projection

Eliminate errors

Elimination of incorrect or omitted dimensions and transfer errors.

Immediate calculations

calculation of areas or spaces immediately after measuring the required points, immediate check of the displayed results

Flexible and portable

no more scaffolding or ladders. Obstacle-free measurement 360° vertically and horizontally also perpendicular to the floor and parallel to the wall

Easy data export and transfer

Easy export of measured CAD files. Compatible with all CNC equipment and most manufacturing and design software.

Measurement errors and unmeasured details

No more handwritten measurements and notes (icon) IMMEDIATE CALCULATIONS - calculation of areas or spaces immediately after measuring the required points, immediate check of the displayed results

Complex measurements

With this system, you will measure angles, arcs, curves and other shapes faster and more precisely - effortlessly and without the need for calculations.

Intuitive software

simple to use, without the need for great effort or special technical knowledge of the user. This type of software usually has an intuitive interface that is logical and easy to understand. It includes clearly labeled icons, simple commands and meaningful visuals.

Measurement errors and unmeasured details

No more handwritten measurements and notes (icon) IMMEDIATE CALCULATIONS - calculation of areas or spaces immediately after measuring the required points, immediate check of the displayed results