Project description

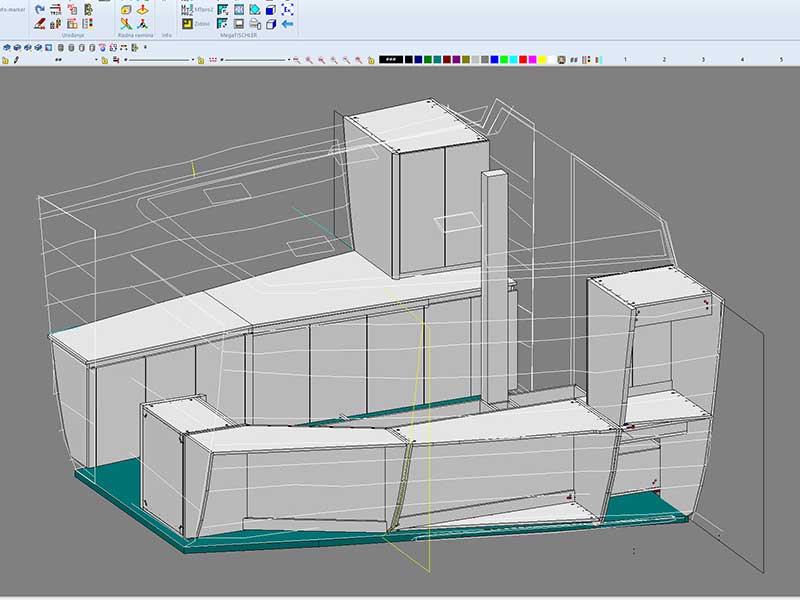

This project shows the comprehensive process of designing, technical preparation and furnishing of the interior of a 54-foot sailboat. The project required precise measurement of the interior dimensions of the sailboat in order to make maximum use of every available millimeter of space, while simultaneously ensuring the functionality and aesthetics of the interior.

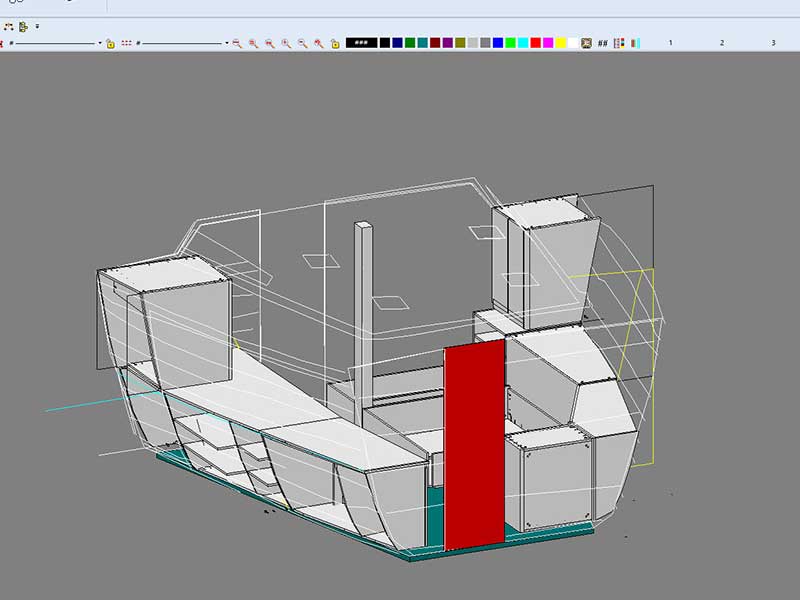

The software MegaCAD / MegaTISCHLERpro was used to complete this demanding task, which enabled detailed design and technical preparation of production. All interior elements were CNC processed in order to precisely match the shape of the hull of the sailboat, which made assembly in the limited space of the ship much easier. This method ensured efficient use of space, proving the value of advanced technologies in the nautical design industry.

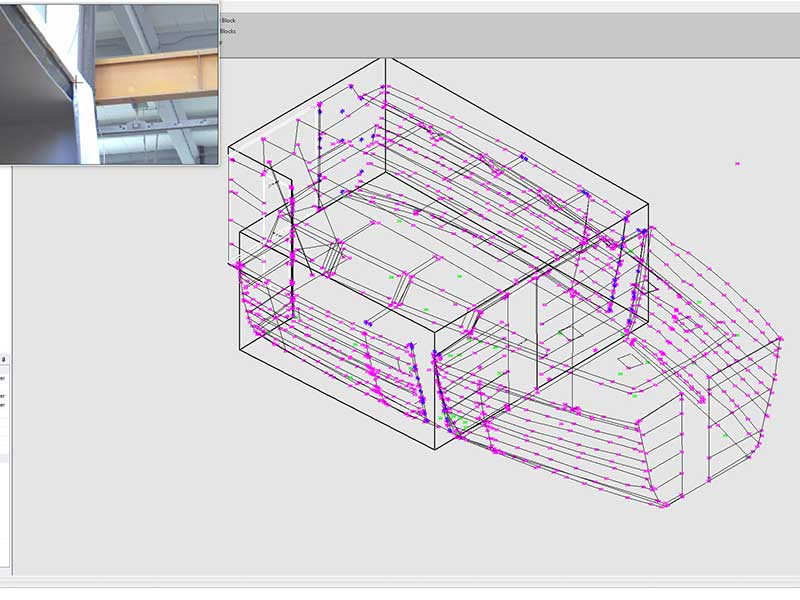

A key part of the project was the detailed process of measuring the interior of the sailboat, which was carried out using an integrated 5MP camera to photograph each measurement point. This method enabled precise mapping of the space and facilitated the interpretation of the obtained data. By scanning horizontal and vertical lines, a detailed 3D model of the ship’s hull was obtained, which eliminated the need to make physical templates or adjust furniture on site.

Flexijet operator for 3D measurement and creation of measurement plans:

Nikola Perković, CAD projektant

Project summary

The project of designing the interior of a sailboat is an excellent example of how the space inside the ship can be optimized with the help of technology, making it functional and aesthetically attractive. The successful implementation of CNC processing and 3D measurement enabled precise production and assembly of interior elements, confirming the importance of digital tools in modern nautical engineering.

- Time required for conventional measurement: impossible to determine

- Time required with Flexijet - 2.5 hours

- Saving time and money: immeasurable

- Efficiency and accuracy: immeasurable