Project description

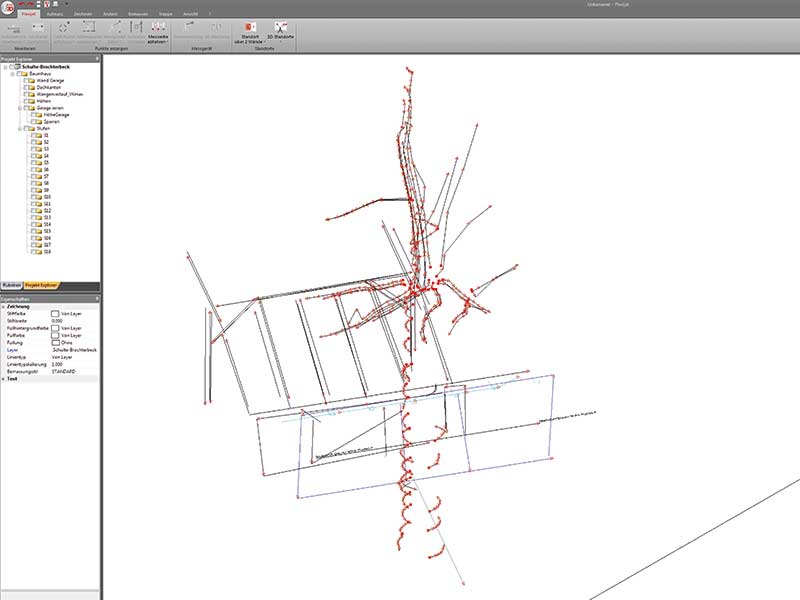

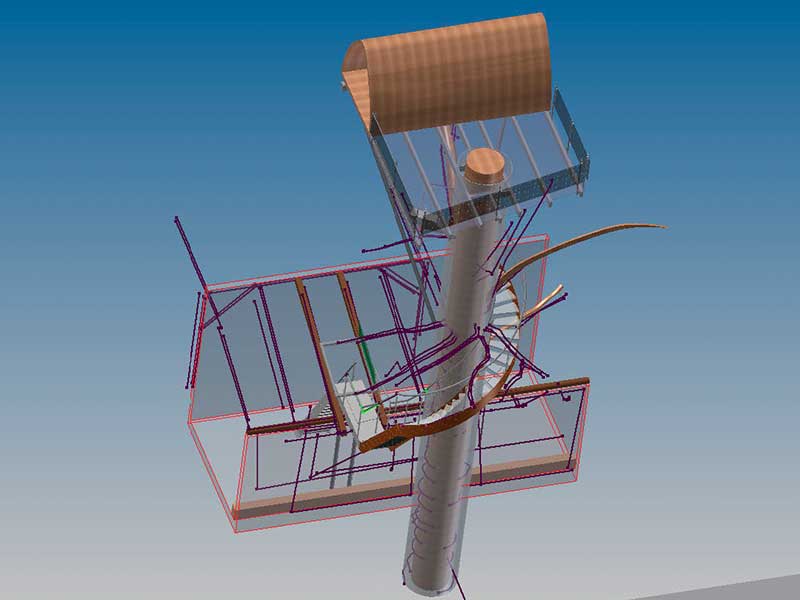

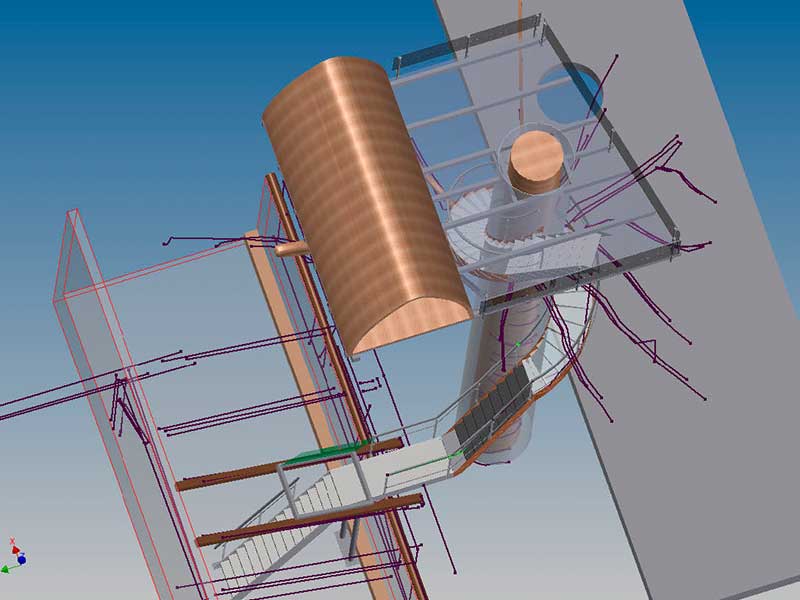

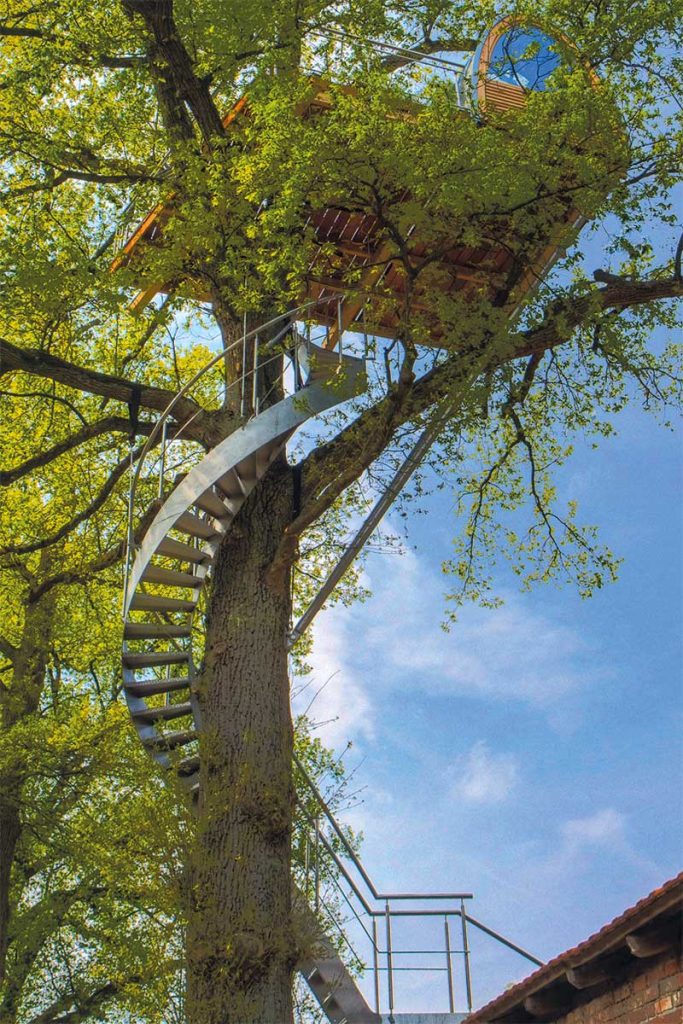

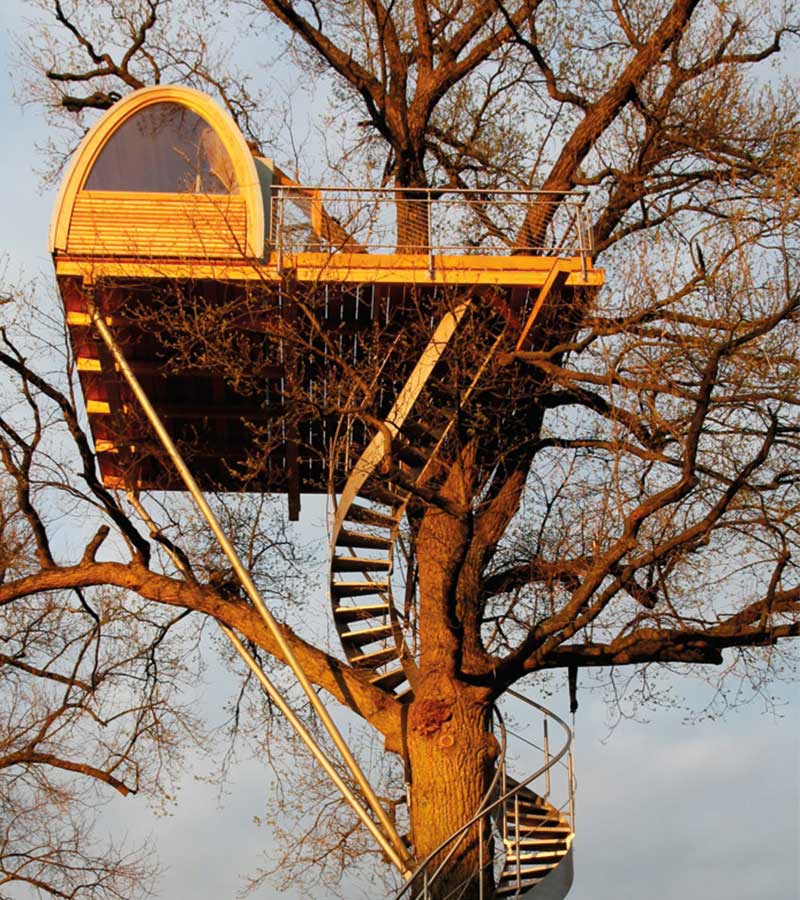

Designing and building a tree house high in the oak tree. The spiral staircase of the treehouse was to pass through the existing building below which the staircase could be accessed. Sounds like a nightmare project! How do you measure and model a tree in CAD? Conventional measurements are certainly out of the question. How do you determine all joints, angles and steps in relation to each other? The answer is of course Flexijet 3D!

Operator: Mr Carsten Thomas, Bielefeld

www.akzente-treppen.de

Contractor: Meschter Metalltechnik

www.meschter.de

Client: Private investor

The contractors stated that they would not have accepted the work on this project if they had not been able to use the Flexijet.

Project summary

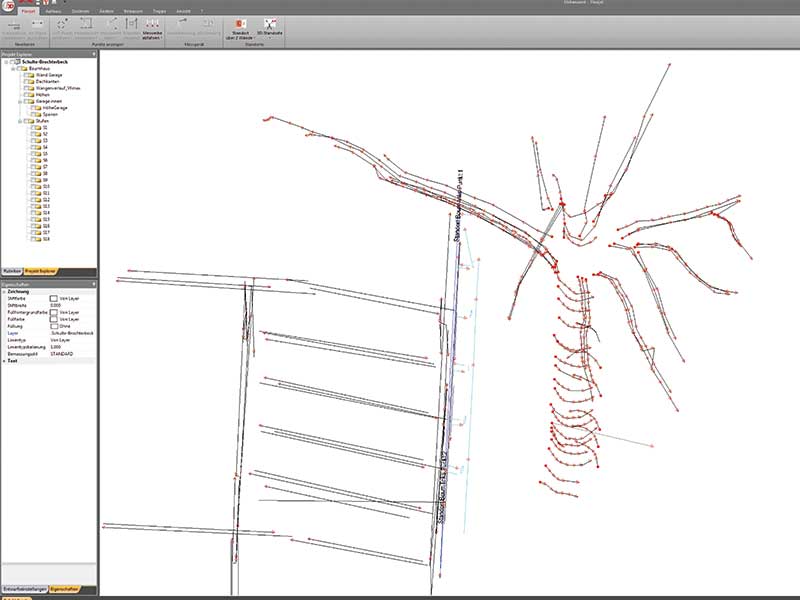

A construction company hired Carsten Thomas to create a 3D CAD model of an existing oak tree using a Flexijet 3D laser measurement system. The Flexijet 3D allowed Carsten to collect all relevant measurements, including the thickness of the oak tree’s trunk and branches, and the building connected underneath. All this was achieved without the use of ladders, ropes or scaffolding. In just 2.5 hours, measurements were safely taken from ground level providing extremely precise dimensions, accurate angles and curves.

Additional advantages of the Flexijet measurements are that we received perfectly precise CAD data of the tree, the position of the branches, diameters, slopes. Flexijet 3D allowed us to measure all relevant data directly in CAD from the ground, without any further aids, ladders, scaffolding, car cranes, additional people or acrobatic climbing

- Time required for conventional measurement: impossible to determine

- Time required with Flexijet - 2.5 hours

- Saving time and money: immeasurable

- Efficiency and accuracy: immeasurable