Project description

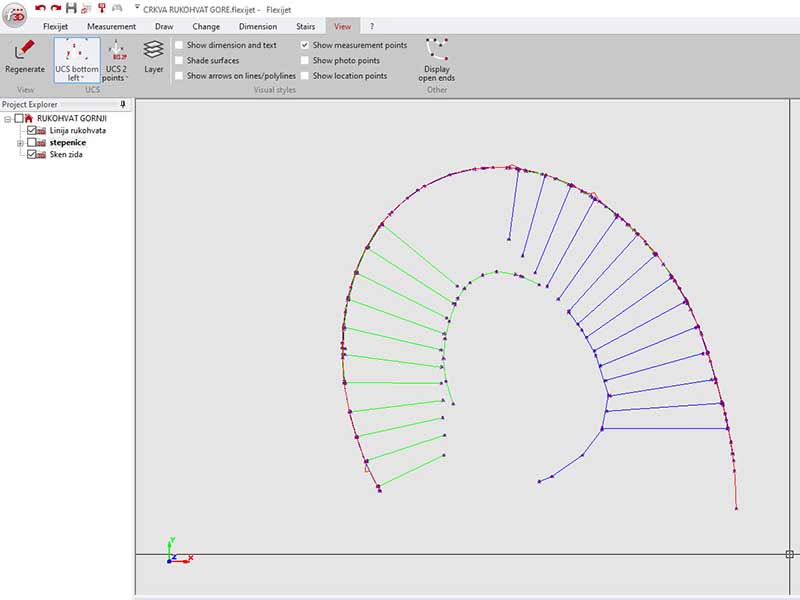

The project in the Church of Our Lady of Lourdes in Zagreb began with a detailed measurement of the positions on the stairs to create a curved handrail. This task required special precision due to the uneven, irregular and rounded walls inside the church. In order to obtain the most accurate result, we applied advanced Flexijet technology, which enabled digital mapping of the walls – crucial for the further development of the project.

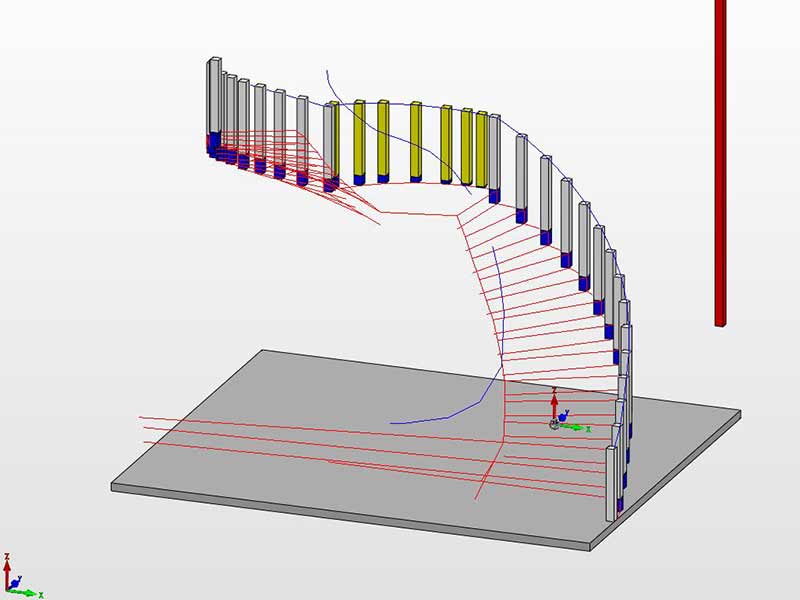

After successful digitization, the team set about creating a detailed 3D model of the space and handrails. This step was crucial for understanding the complexity of the space and for production planning. The 3D model of the handrail was used to create CNC files for the individual handrail segments.

The handrail was manufactured using a method of laminating massive slats, which were simultaneously bent in a mold. This process required a high level of skill and precision, as each handrail segment was unique and tailored to the specific measurements and curvatures of the wall.

MegaCAD software was used to develop the rounded surfaces, which allowed for the creation of the exact appearance of each slat.

Flexijet operator for 3D surveying and preparation of survey drawings: Edo Aganović

Technical preparation: Stolarija Bedenic

Project contractor: Stolarija Bedenic

Project summary

The final result was impressive. The handrail, perfectly integrated into the architecture of the church, was a combination of traditional carpentry skills and modern technological solutions.

The project of making a curved handrail for the Church of Our Lady of Lourdes is another in a series of successful projects that testifies to the uniqueness of Flexijet. It ensured the possibility of combining traditional techniques with advanced technology.