About the project:

Today, we face rapid technological changes that affect the way we live and work. Digital transformation and sustainable development are two key components shaping the future of business. In this case study article, we will show how we innovatively used technology to improve the pool lining process on a project and how this contributes to sustainable development.

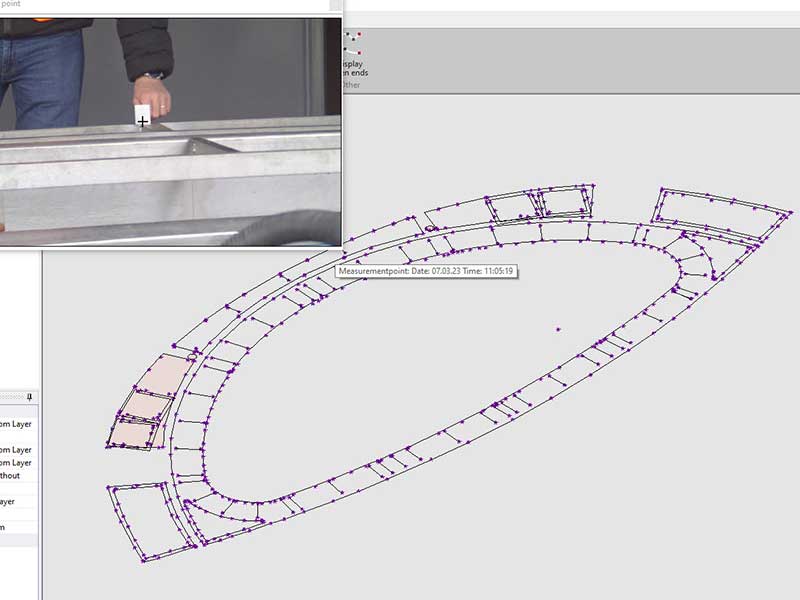

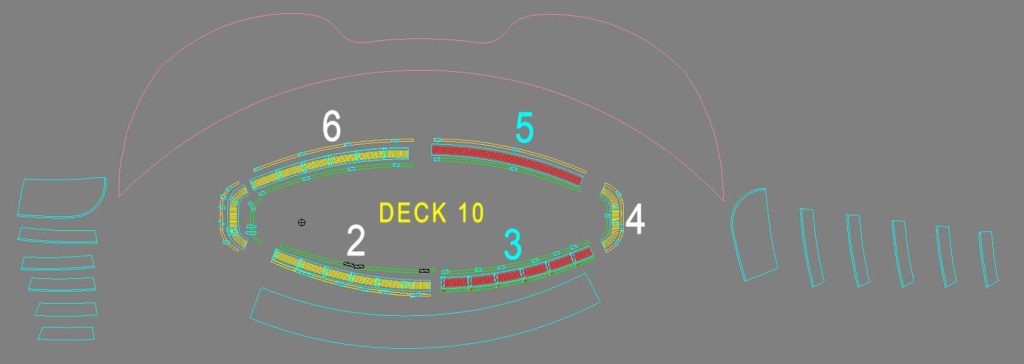

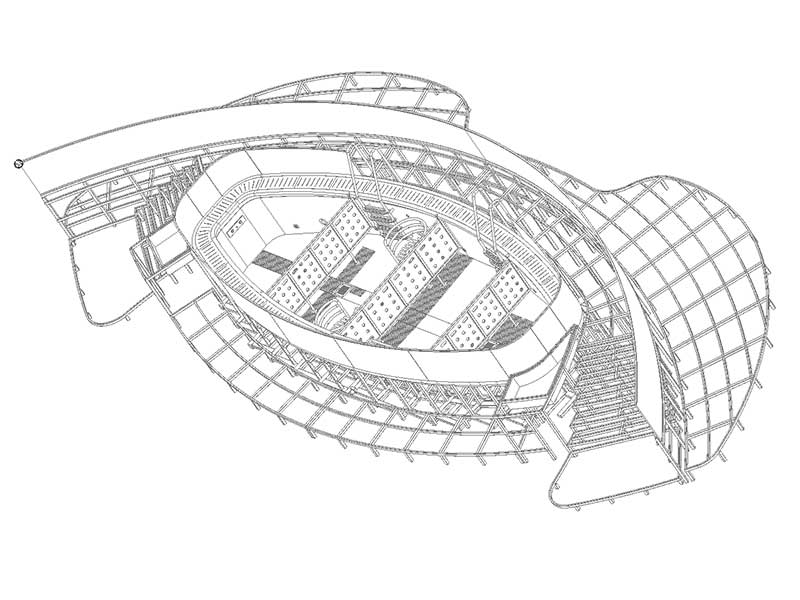

The project involved 3D measurement of positions for creating grilles and lining around the pool and its surroundings. Kerrock material was used, while the substructure was made of stainless steel. In addition, the positions of the arcs for a bench to be constructed from one piece were measured. Flexijet technology was used for measuring arcs and cross-fastenings, which allowed for easy construction of the finished product and the creation of CNC documentation.

Through innovative use of digital technologies, this project contributes to sustainable development. By using materials like Kerrock, which is durable and weather-resistant, the need for regular maintenance and replacement is reduced. Moreover, the stainless steel substructure provides additional strength and longevity, reducing the negative impact on the environment.

Flexijet operator for measurement and preparation of measurement drawings: Edo Aganović i Josip Hruškar

Project executor: Duo Step

Client: Private investor

Project summary

Digital transformation played a key role in this project. By using advanced Flexijet technology, measurement became more precise and efficient. Flexijet enabled our team to quickly and accurately measure complex shapes, reducing the need for manual labor. This, of course, saved an extraordinary amount of time and other resources.

- Time taken - manual methods: 20 hours

- Vrijeme potrebno sa Flexijetom - 4 sata

- Saving time and money: immeasurable

- Efficiency and accuracy: immeasurable