About the project:

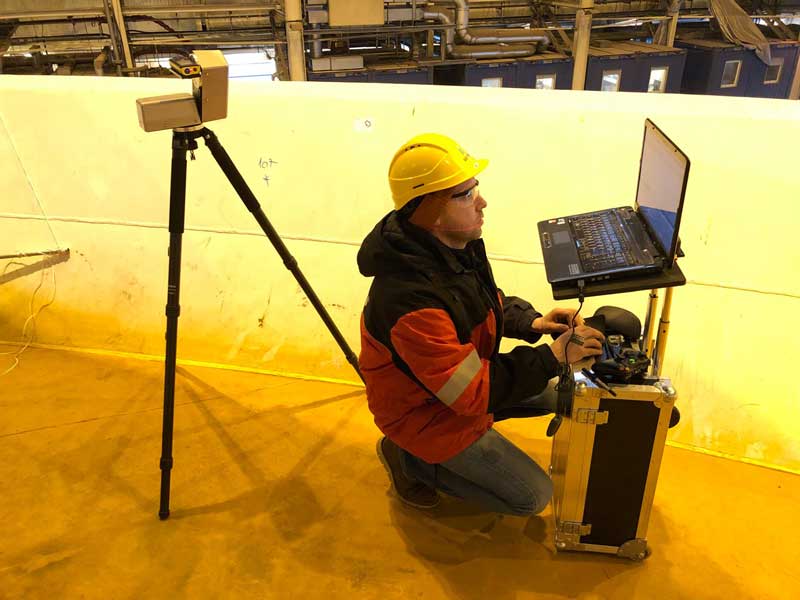

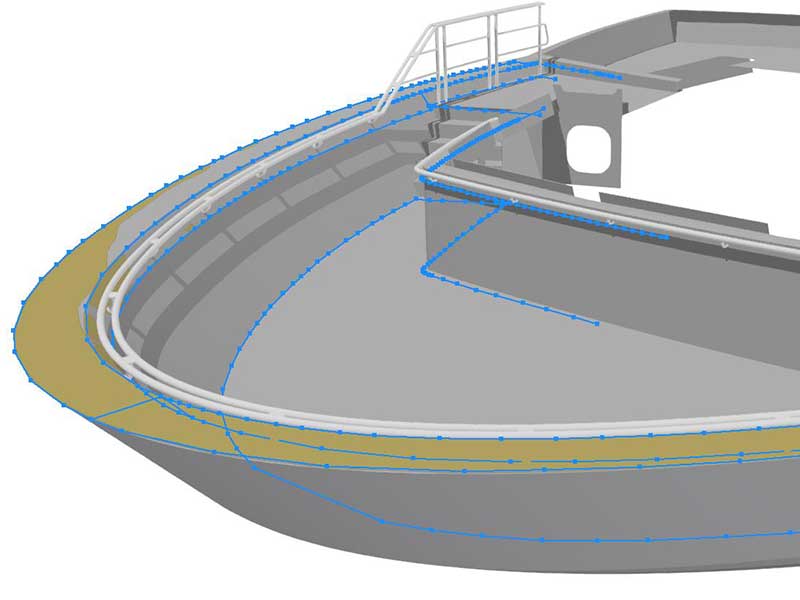

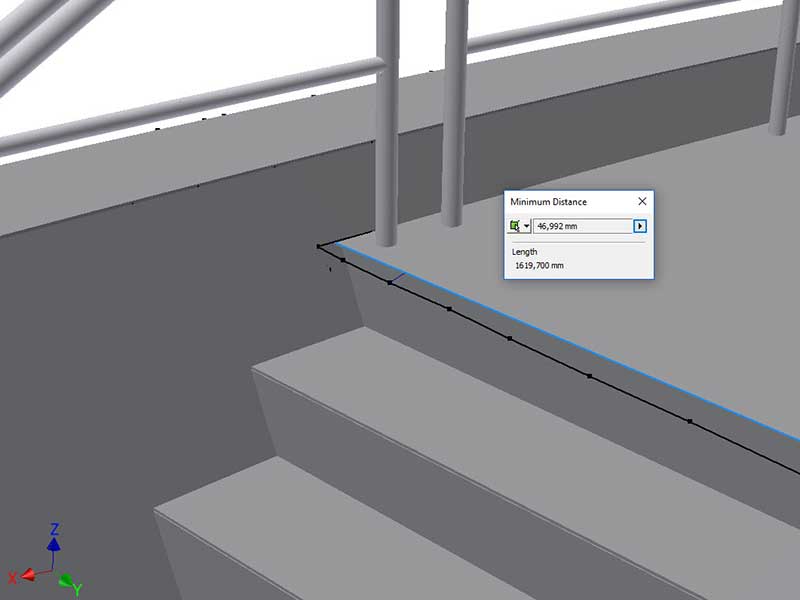

In 2018, we accepted the cooperation with the company Smed Engineering – Norway, which hired Flexijet East for the ULSTEIN shipyard to check the finished condition of the ship X BOW – Olivia O – with the aim of determining possible irregularities that could affect the assembly and installation of stainless steel fences and handrails, and to extend the duration of the works, thereby increasing the price of the project.

These features help engineers and designers improve the quality of their products and reduce development time. By using the latest technology and cutting-edge tools, the team was able to record all irregularities and defects that could affect further work.

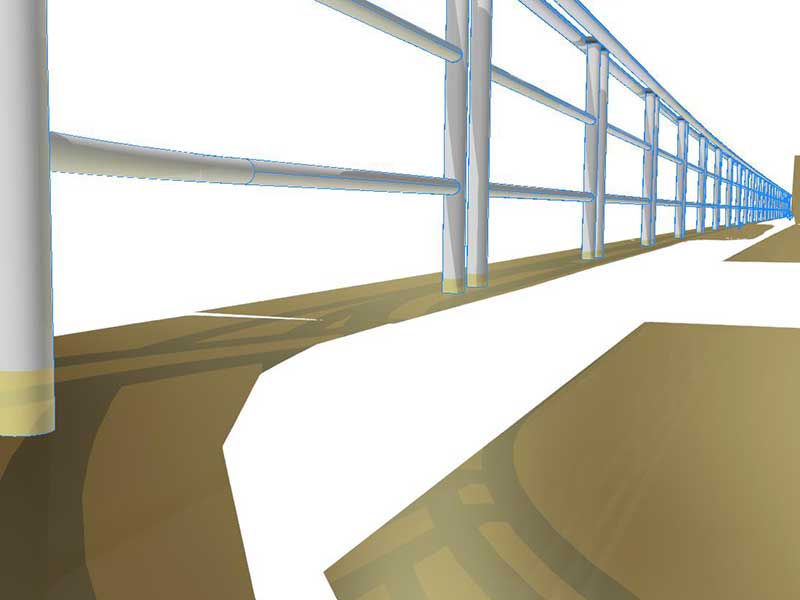

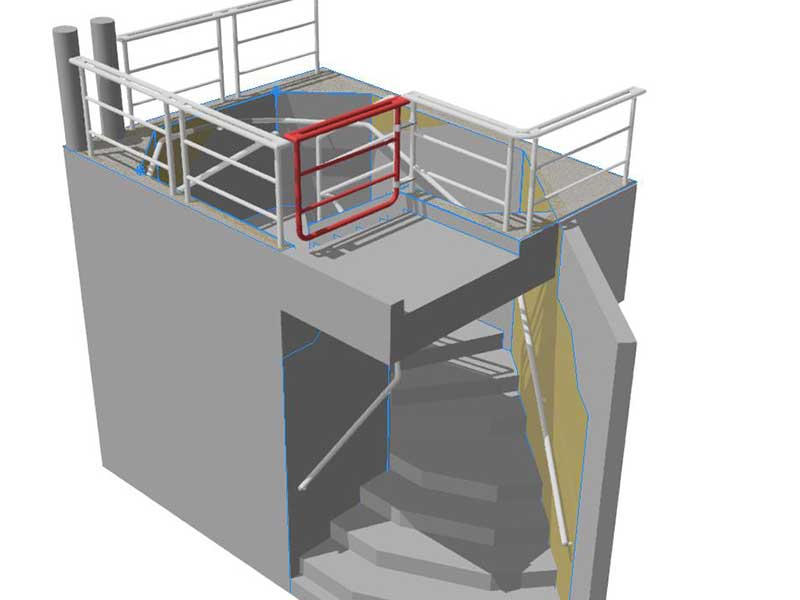

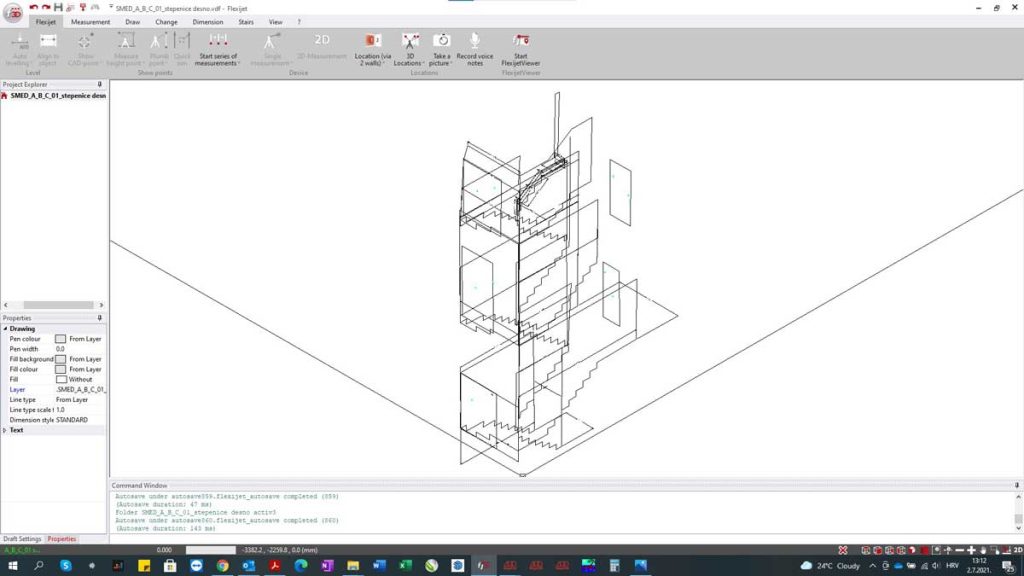

In order to solve the identified irregularities, in addition to our Flexijet, the most modern technology was used in the construction and technical preparation in the Autodesk Inventor program.

Inventor offers advanced features such as animation and simulation, which allow users to test and analyze their models under different conditions. This includes the ability to check mechanical properties, thermal analysis, and fluid flow analysis. These features help engineers and designers improve the quality of their products and reduce development time.

Flexijet operator for measurement, preparation of measurement drawings and technical preparation: Edo Aganović i Nikola Čubranić

Project executor: Smed Engineering BH d.o.o.

Project summary

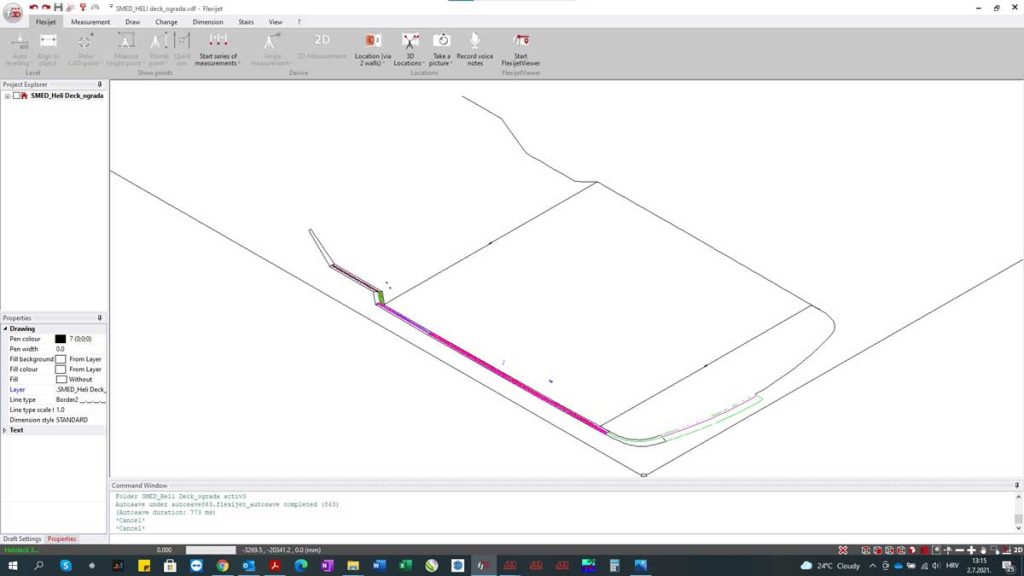

By using different software, technologies, and approaches, we were able to save time and money for our clients on this project, and ensure fast and efficient project execution.

- Time taken - manual methods: 7 – 10 days

- Time taken - Flexijet 3D: 4 working days

- Time Saved: 6 days

- Efficiency and accuracy: immeasurable