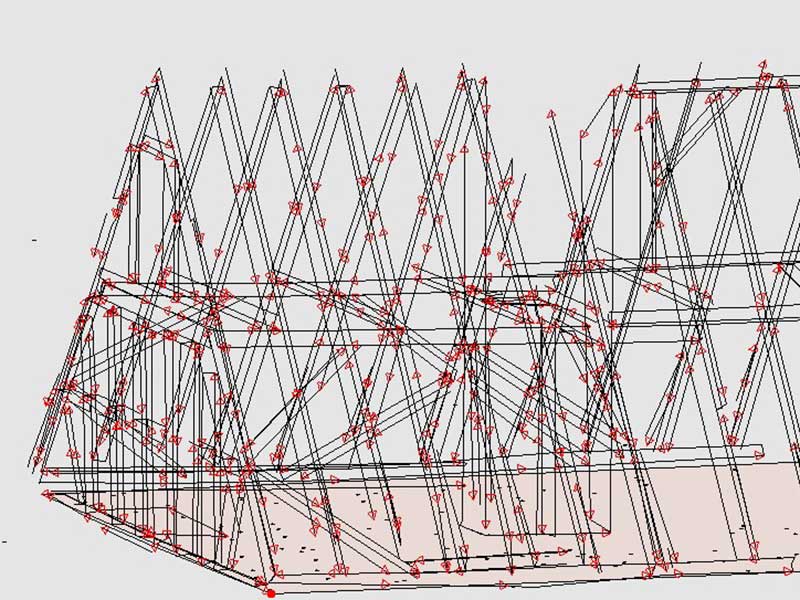

3D measurement of steps and positions on the structure for point support spider fittings for glass

3D measurement of steps and positions on the structure for point support spider fittings for glass Project description One of the clients who recognized the benefits of the approach we constantly point out, which is increased precision while saving time and money, is the company Drvona from Karlovac. It has only been a year since the beginning of the successful cooperation between us. Never the less, the biggest benefit of Flexijet measurement, which Drvona quickly discovered, was reduced measurement errors and easier execution and assembly of their products. One of the projects we worked on together at the beginning of last year was the furnishing of a luxury apartment in the Podsljeme zone in Zagreb. We called that project Project M, and below is a part of it: pictures that show the final result of the 3D measurement, execution and assembly of the custom-made kitchen. Flexijet operator for 3D measurement and surveying drawings: Josip HruškarTechnical preparation: Articus d.o.o.Project manager and installation: Ambientalni Dekor j.d.o.o. Project summary The success of this project testifies to the power of digitization in the furniture fabrication process—from initial measurements and technical preparation to fabrication and final installation. It confirms that the proper combination of technology, expertise, and precision is key to the successful realization of even the most complex projects. Flexijet measurement Flexijet measurements Technical preparation