Project description

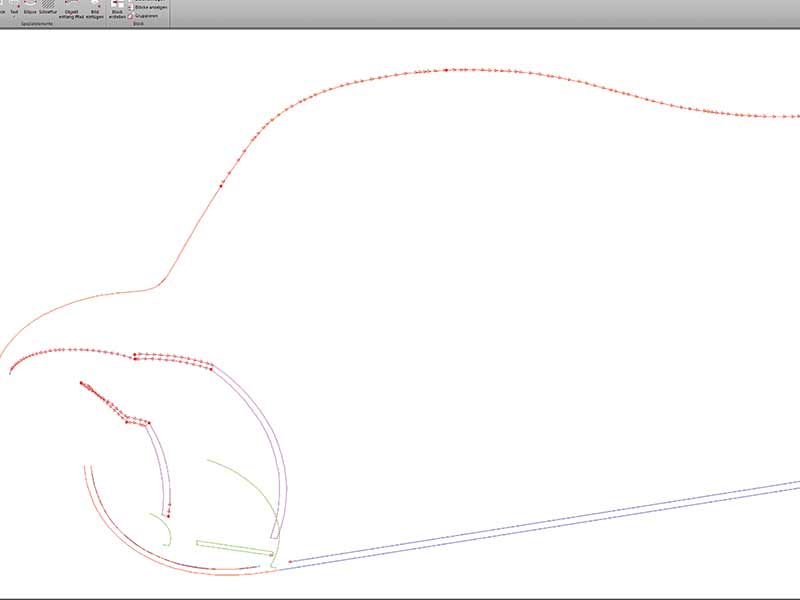

Johannes Wortmann, a colleague and Flexijet user from Balve (Germany), carried out the production of curved handrails for the new gymnasium building in Bochum, using the Flexijet 3D to measure the curved concrete surfaces of the building structure. structure.

The data obtained from the measurement was sent to the CNC machine center in Balve, where the handrails were made of solid oak wood. Thanks to the precise measurement, production on the CNC machine could be carried out with millimeter accuracy in all three axes. On-site assembly was possible without additional repairs or adjustments to completed parts – everything was a perfect fit immediately.

In addition to saving time and money during measurement and assembly, Flexijet 3D provides security in planning, construction and production, because it is based on reliable data.

Johannes Wortmann stated: “Without the Flexijet precision and workflow the realization would not have been economical. We wouldn’t have taken on this project without Flexijet.”

Project summary

With Flexijet 3D, you get millimeter precision, exact angles and radius – and you have access to the data during the measurement, that is, on the spot. Flexijet 3D provides safety and professionalism from measurement to assembly.

Flexijet 3D measurement system enabled significant time and money saving in this project.

- Time required for conventional measurement: 40 hours

- Time required with Flexijet - 14 hours

- Time saved: 26 hours

- Efficiency and accuracy: immeasurable