Project description

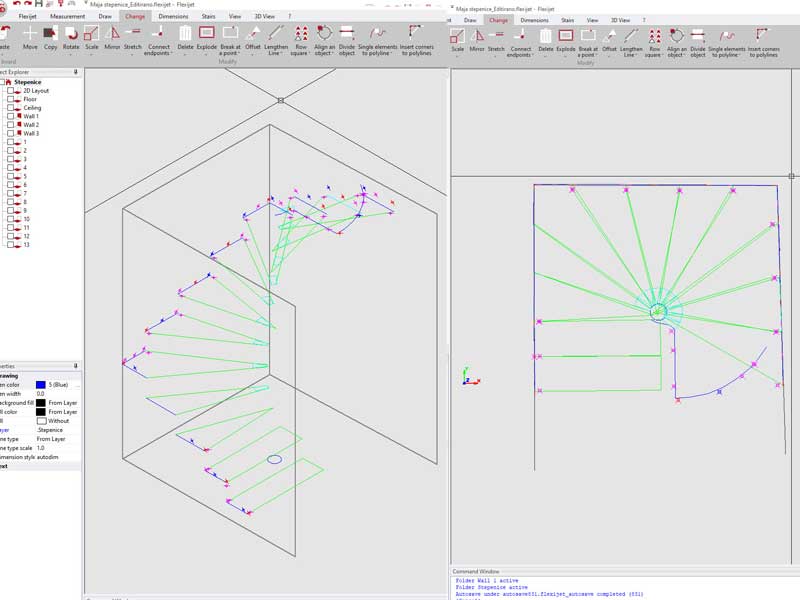

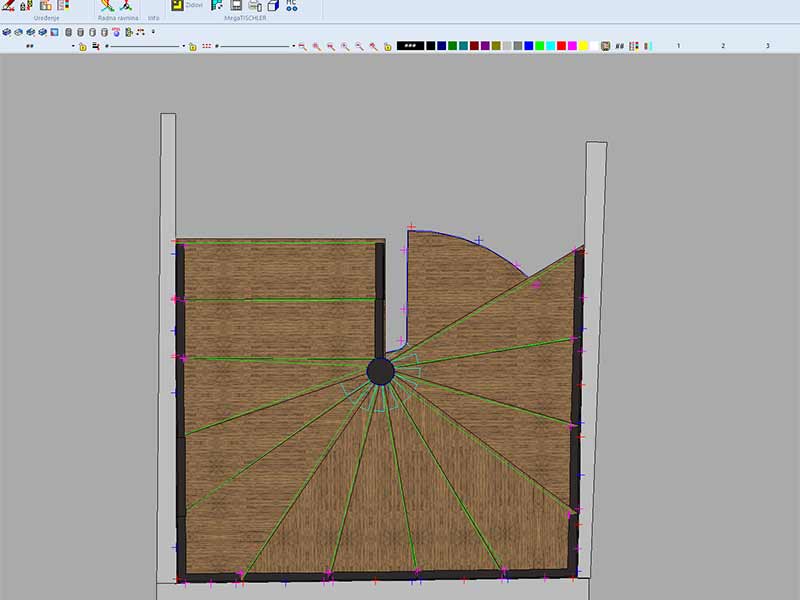

Measurement of the metal structure and walls for making treads for a circular staircase.

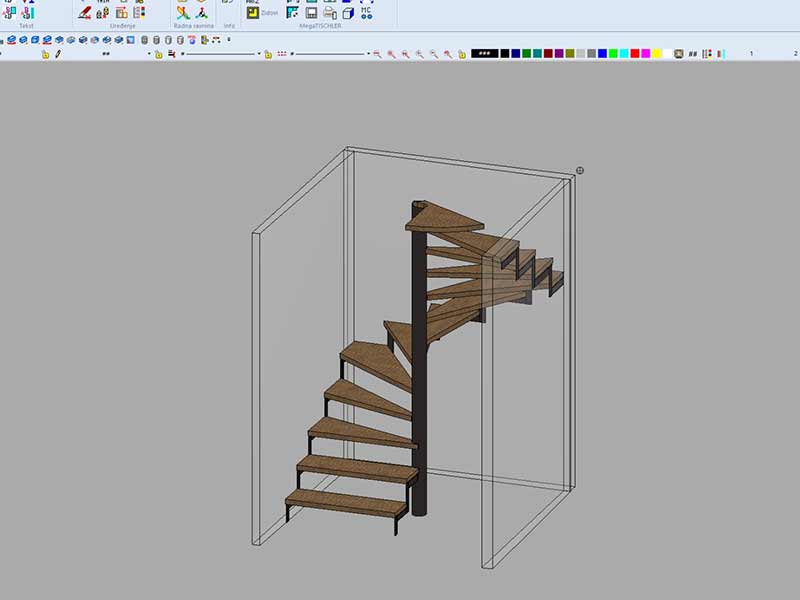

Due to the specific position of the staircase, the measurement alone would not be enough and the client would be required to make templates as well. Fortunately, with the combination of the Flexijet device and the MegaTISCHLERpro program, we shortened the process and it was enough to measure and construct the treads and create a CNC program for processing the treads.

The advantages of the Flexijet measurement are that we received extremely precise data on angles, heights and curves. Additional costs for material for making templates, aids such as ladders, scaffolding, laser levels and tools for making templates weren’t needed. All we used was a laptop and a Flexijet device. All measurement data are in CAD and technical preparation and creation of CNC programs can be started immediately.

Flexijet operator for 3D measurement and creation of measurement plans: Studio Element d.o.o.

Client and executor of the project: Pandeco d.o.o.

Project summary

Precise measurement and planning, combined with quality execution ensured the successful completion of this project.

- Time required for conventional measurement: 8 hours

- Time required with Flexijet - 1 hour, technical preparation and creation of CNC program: 2 hours

- Time saved: 5 hours

- Efficiency and accuracy: immeasurable