Project description

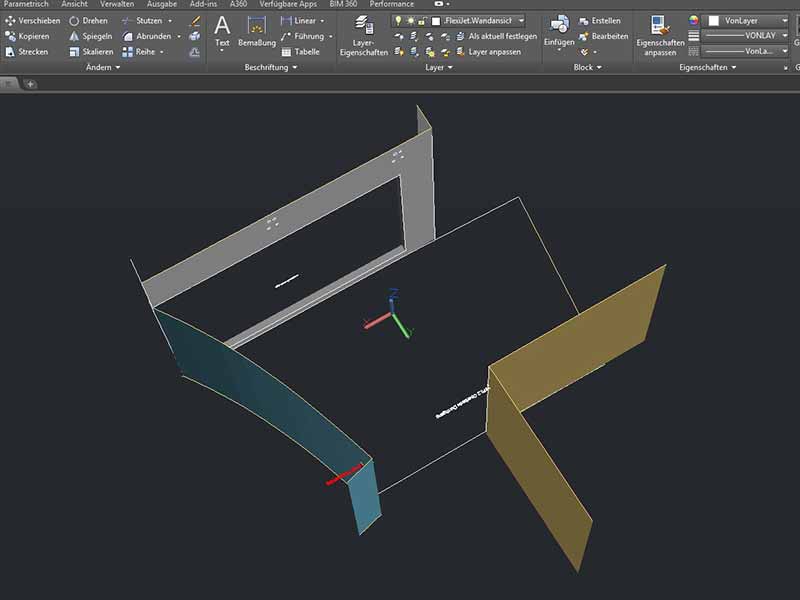

The primary task of the construction company specialized in the production of metal structures was to create a canopy that will provide covered access to the house. The client envisioned a canopy with three sides which would be placed above the front door and on the curved part of the blue wall. The implementation of the project was already under the threat of failure due to complications that arose during measurement. On the first attempt, it was impossible to accurately measure the curvature of the wall using a tape measure and a handheld laser. During the next on-site meeting, several company employees spent hours making templates 2 to 3 meters high. Unfortunately, this approach did not result in usable data either. Due to heavy rain, the cardboard templates became unusable.

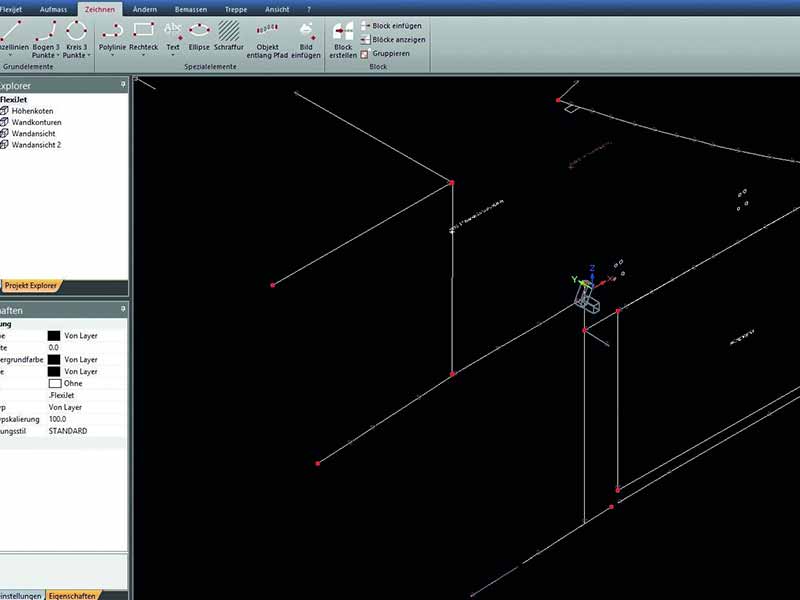

The solution to the measurement problem was found in the application of the Flexijet 3D laser measurement system, which allows simultaneous measurement and drawing.

Contractor: Konrad Schwegler, Fellbach

Client: Privatni investitor

Project summary

Konrad Schwegler, the measurement service provider, successfully performed all the necessary measurements on site in just 1.5 hours. A full CAD drawing, with all the correct angles and radii, was immediately available. As a reliable basis for further planning, the three-dimensional DXF file was forwarded to the design department.

- Time required for conventional measurement: 10 h

- Time required with Flexijet - 1:30 h

- Time saved: 8:30 h

- Efficiency and accuracy: immeasurable