Project description

We measured the stairs for a private investor and installed the front door panels to allow access to the boilers for service and maintenance. The stairs needed to be measured for angles and irregularities to allow us to make the door panel as precisely as possible. During the measurement, we found a lot of irregularities in the construction of the staircase itself. With such a precise measurement, we were able to adapt the future furniture to the maximum during the design process and ease the installers’ troubles during assembly.

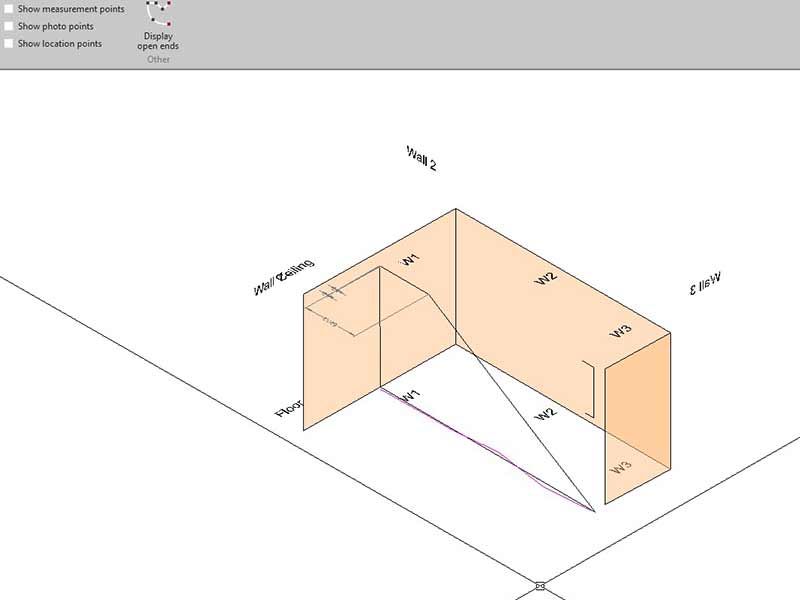

In this project, we have shown how measurement with Flexijet technology offers fast and precise space measurement, with significant savings in time and resources. All collected data is available in CAD format, and design can be started immediately.

Client: Private investor

Contractor: Studio element d.o.o.

Project manager: Edo Aganović

Project summary

Compared to conventional measuring methods, measuring with the Flexijet device saves approximately 2.5 hours, eliminating the need for time and material needed to create templates. In addition, the Flexijet measurements provide perfectly precise data on all objects in the space, which facilitates the planning and execution of projects. Overall, our innovative method brings efficiency, precision and practicality in the process of spatial analysis and design.

- Time required for conventional measurement: 3 hours

- Time required with Flexijet - 30 minutes

- Time saved: 2 hours and 30 minutes

- Efficiency and accuracy: immeasurable