Project description

In the following, we would like to present the project that involved the measurement, production, supply, and installation of the staircase railing in a private house in Drškovci (Požega). The goal of the project was to ensure a precise and functional railing for the staircase connecting three floors of the house, with the specific challenge of uneven walls and irregular angles of the staircase.

Measurement

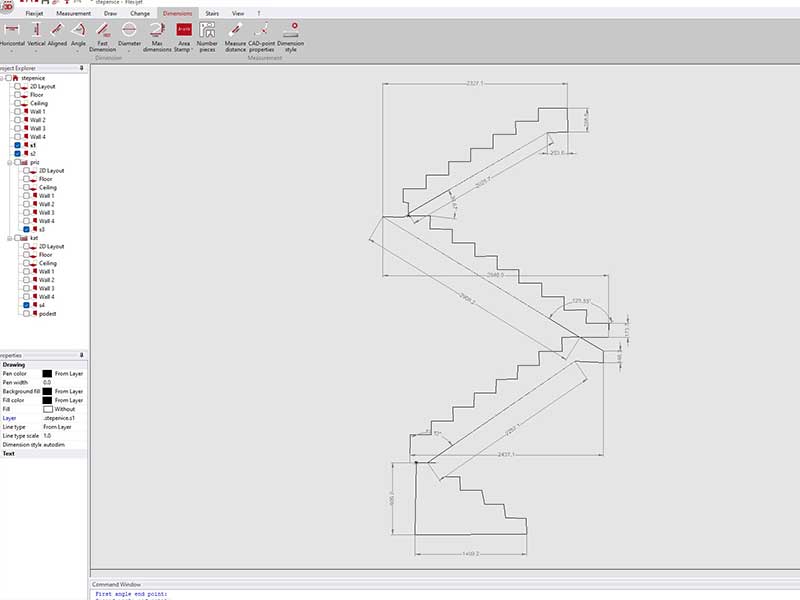

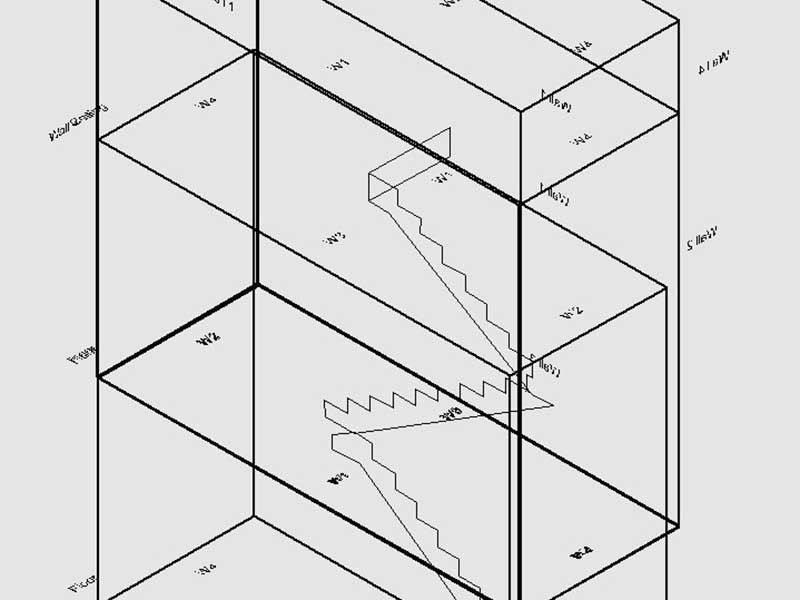

The first step of the project was the detailed measurement of the staircase. Using Flexijet 3D technology, the team was able to accurately measure all flights of the staircase across the three floors. This allowed for the precise determination of the slope, position of the railing, and the placement of the supports and attachments for the railing. Accurate 3D measurements were crucial to ensure all elements were precisely aligned with the existing structure of the house.

Design and preparation

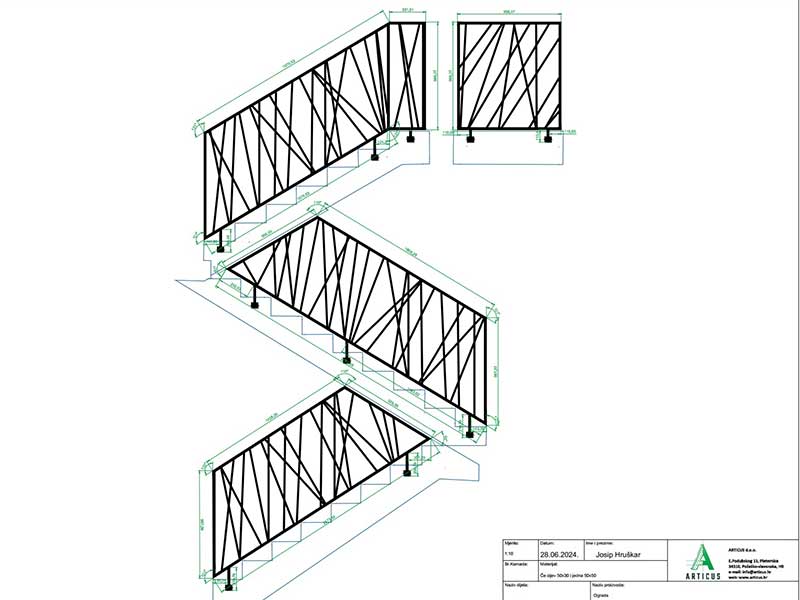

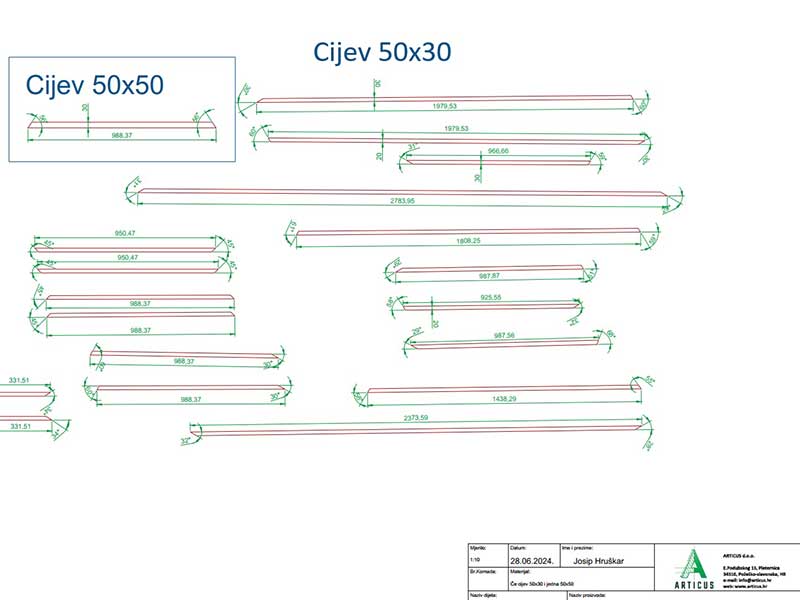

After the measurements, the data were imported into CAD software. This enabled the creation of detailed drawings of the railing with exact dimensions and angles, prepared for production. The CAD drawings served as the foundation for the further production of the steel railing elements.

Production

Steel tubes were cut to precise dimensions and angles from the CAD drawings. All elements were welded and powder-coated, making them ready for installation. Since steel does not allow for on-site adjustments, the precise 3D measurements eliminated the need for a trial assembly. The finished product was delivered directly from production to the site.

Installation

The installation of the staircase railing was carried out without any issues. Due to the precision of the 3D measurements, the finished elements perfectly matched the existing staircase. here was no need for additional modifications or adjustments during the installation of the complete railing.

Final works

The last part of the staircase was made from a single piece, also thanks to the precise 3D measurements. This way, it was possible to avoid phased work, which would have been necessary with irregular angles without accurate measurements.

Project summary

This project is an example of how modern technology and careful preparation can ensure high-quality results even under the most challenging conditions.

The project involving the measurement, production, supply, and installation of the staircase railing in Drškovci demonstrated the importance of precise measurement and careful preparation. The use of Flexijet 3D technology and CAD software enabled error-free production and installation, ensuring that the railing perfectly matched the existing staircase structure. The investor was extremely satisfied with the final result, further confirming the quality of work provided by our partner, ARTICUS d.o.o.

Flexijet operator for 3D measurement and creation of measurement plans:

Articus d.o.o.

Representative for the Flexijet 3D device and provider of 3D measurement services:

Studio Element d.o.o.