Precise measurement and reliable execution in an irregular space Caffe bar Leonardo

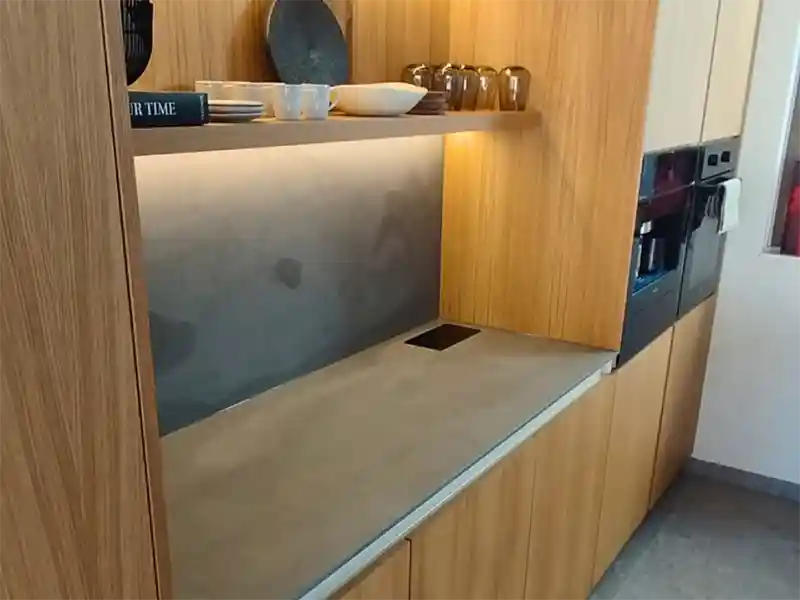

Precise measurement and reliable execution in an irregular space Caffe bar Leonardo Project description The renovation project of the Caffe Bar Leonardo in Split required a high level of precision, good organization and technically reliable execution. It is a space that remained in use for most of the work, while simultaneously realizing a demanding interior concept with clearly defined aesthetic and functional goals. The concept, space design and execution solution are signed by Tassotti Design, while Studio Element d.o.o. was responsible for precise Flexijet 3D measurements of the actual situation, technical development of the draft, production and installation of designed upholstered furniture, wall panels, shelves, bar, mirrors, etc. Project challenges The area of Caffe bar Leonardo had several specific challenges: irregular walls and deviations from ideal geometry, carrying out work in several phases, working in an active catering facility, which required precise assembly planning and minimal tolerances in execution. In such conditions, classical measurement methods do not provide a sufficient level of security, because they cannot fully capture the actual geometry of the space or ensure consistency between the designed and constructed state. Solution: Flexijet 3D surveying and technical preparation Studio Element conducted a millimeter-accurate 3D space measurement on the project using Flexijet technology. This system allows for: precise recording of the actual geometry of the space, recording all irregularities of walls and lines, reliable technical basis for the production of all elements The obtained measurement data served as the basis for the safe and precise realization of the design concept, the sending of technical preparation drafts to production, and without the need for improvisations or subsequent adjustments to the object during assembly. Results and added value The application of Flexijet technology and the professional approach of Studio Element have achieved the following results: complete harmony of the design solution and performance, precise production of all elements according to the actual measurements of the space, neat and functional assembly without deviations, continuous technical support during all phases of the project. Each interior element was realized by Studio Element d.o.o. completely in accordance with the design by Tassotti Design, with a high level of accuracy and finishing quality. Why does Flexijet make a difference? On projects with irregular spaces and complex details, Flexijet 3D allows for: removing uncertainty in the implementation phase, reducing the risk of errors and additional procedures, clear and reliable technical basis for all project participants, faster and better realization of design solutions. Conclusion The Caffe bar Leonardo project confirms how precise measurement of the actual condition of the space is crucial for the successful realization of demanding interiors. Studio Element d.o.o. has, thanks to Flexijet 3D technology, provided a reliable basis from start to finish for the implementation of a design solution signed by Tassotti Design, without compromising on quality or functionality. Such projects clearly show that top-quality realization results from a combination of quality design, precise technology and reliable technical preparation of production up to assembly. Studio Element d.o.o. – Flexijet 3D device and measurement representativeDolac 1, Zagreb, info@3dmjerenje.comConcept, design and implementation solution: Tassotti Design, office@tassoti.com, +385 95 1122233Technical preparation, production and installation: Studio Element d.o.o., Dolac 1, Zagreb, info@studioelement.com, +385 98 472900 Flexijet measurement Flexijet measurements Flexijet measurement

Precise measurement and reliable execution in an irregular space Caffe bar Leonardo Read More »